권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

Title Page

Abstract

Contents

Abbreviations and annotations 15

CHAPTER 1. INTRODUCTION 17

1.1. Background and Motivation 17

1.1.1. Overview of lubrication technologies 17

1.1.2. Challenges in Lubrication 19

1.1.3. Introduction to Nanoparticles in Lubricating Oils 20

1.1.4. Rationale for Nanoparticle Modification 21

1.1.5. Relevance to Industry and Applications 22

1.1.6. Research Gap and Need for Investigation 24

1.2. Objectives of the Study 26

1.2.1. To Investigate the Tribological Properties 26

1.2.2. To Assess the Rheological Behavior 27

1.2.3. To Examine the Thermal Conductivity Enhancements 29

1.2.4. To Compare Different Nanoparticle Types 30

1.2.5. To Provide Recommendations for Practical Implementation 31

1.3. Scope and Significance 32

1.3.1. Scope of the Research 32

1.3.2. Significance of the Research 33

1.4. Organization of the Thesis 34

CHAPTER 2. LITERATURE REVIEW 35

2.1. Nanoparticles in Lubricating Oils 35

2.2. Tribological Properties of Lubricants 40

2.3. Rheological Behavior of Lubricating Oils 43

2.4. Thermal Conductivity in Nanolubricants 46

CHAPTER 3. Experimental Methodology 49

3.1. Synthesis of nanoparticles 49

3.1.1. Sonochemical Synthesis of CuO Nanoplatelets 49

3.1.2. Sole-gel Synthesis of CuO NBs 50

3.1.3. Bio-Synthesis of CeO₂ nanoparticles 51

3.2. Characterization and experimental setup used. 53

3.2.1. Characterization 53

3.2.2. Experimental Setup 61

3.2.3. Preparation of Nanolubricants 71

3.2.4. Testing Conditions 76

CHAPTER 4. Results and Discussions 79

4.1. Nanolubricants Prepared using CuO nanoplatelets with fully synthetic motor oil. 79

4.1.1. Structural Characterization 79

4.1.2. Morphological Characterization 80

4.1.3. Effect on Morphology afterMixing in Oil 82

4.1.4. Dispersion of Nanoparticles (NPs) 84

4.1.5. Zeta Potential of Nanolubricants 85

4.1.6. Tribological Characterization 86

4.2. Nanolubricants Prepared using CuO nanoballs with PAO oil. 94

4.2.1. X-ray diffraction (XRD) 94

4.2.2. Raman spectroscopy 95

4.2.3. FTIR analysis 96

4.2.4. Morphological characterization 99

4.2.5. Dispersion and stability of NBs 102

4.2.6. Zeta potential 105

4.2.7. Viscosity analysis 106

4.2.8. Rheology 109

4.2.9. Thermal analysis 111

4.2.10. Tribological characterization 113

4.2.11. Wear tracks 115

4.2.12. Wear rate 119

4.3. Nanolubricants Prepared using bio-synthesized CeO₂ nanoparticles with PAO oil 122

4.3.1. XRD diffraction 122

4.3.2. Morphological characterization 123

4.3.3. FTIR characterization 125

4.3.4. TG-DTA analysis 126

4.3.5. Rheological properties 128

4.3.6. Relation between Viscosity and temperature 130

4.3.7. Relative Viscosity 131

4.3.8. Viscosity Index 132

4.3.9. Thermal Conductivity 133

4.3.10. Tribological Properties 135

CHAPTER 5. CONCLUSIONS 137

5.1. Summary of Findings 137

5.2. Implications of the Study 137

5.3. Recommendations for Future Research 139

BIBLIOGRAPHY 141

SUMMARY IN KOREAN 155

Figure 1. Lubrication technologies 18

Figure 2. Challenges in Lubrication 20

Figure 3. Schematics of types of tribometers 42

Figure 4. Synthetization of CuO Nanoplatelets. 50

Figure 5. Synthesis of CuO nanoballs 51

Figure 6. Bio-synthesis of CeO₂ nanoparticles 53

Figure 7. X-ray Diffractometer 55

Figure 8. Micro-Raman Spectrophotometer 56

Figure 9. Fourier Transform Infrared Spectrometer 58

Figure 10. Scanning Electron Microscope (SEM) 59

Figure 11. Transmission Electron Microscope (TEM) 60

Figure 12. Zeta potential meter 61

Figure 13. Schematic diagram of fabricated reciprocating tribometer 63

Figure 14. Dimensions of pin and plate 63

Figure 15. Experimental and data acquisition setup of fabricated reciprocating tribometer 64

Figure 16. Photograph of fabricated reciprocating tribometer. 65

Figure 17. Reciprocating tribometer: schematic diagram 66

Figure 18. Reciprocating tribometer: actual image 67

Figure 19. Rheometer 68

Figure 20. Thermal Properties Analyzer (TEMPOS) 70

Figure 21. High-speed confocal laser scanning microscope (NS-3500) 71

Figure 22. Fully synthetic motor oil and Polyalphaolefin (PAO) Oil 73

Figure 23. Nanolubricant prepared with varying weight percent of CuO nanoplatelets. 74

Figure 24. Nanolubricant prepared with varying weight percent of CuO nanoballs. 75

Figure 25. Nanolubricant prepared with varying weight percent of CeO₂ nanoparticles. 76

Figure 26. XRD pattern of CuO NPs. 79

Figure 27. Raman spectra of CuO NPs. 80

Figure 28. (a-d) SEM images and (e) EDS of CuO NPs. 81

Figure 29. (a,b) FE-TEM images and (c) EDS and mapping of CuO NPs. 82

Figure 30. (a) Samples of nanolubricant on ITO glass; (b) SEM image of CuO NPs after mixing in oil; and (c) EDS of CuO NPs after mixing in the lubricating oil. 83

Figure 31. (a,b) FE-TEM images of CuO NPs after mixing in the lubricating oil; and (c) EDS and mapping of CuO NPs after mixing in the lubricating oil. 83

Figure 32. Comparison between the sedimentation of CuO NPs after 15 days with (a) all samples and (b) 0.1% CuO NPs concentration. 85

Figure 33. Zeta Potential of all concentrations of CuO NPs. 86

Figure 34. COF under dry and pure synthetic oil conditions. 88

Figure 35. COF of pure synthetic oil and CuO NPs nanolubricants. 89

Figure 36. SEM image of wear track for (a) 0.05, (b) 0.1, (c) 0.15, and (d) 0.2 weight percent concentration of CuO NPs; (e) EDS of wear surface. 90

Figure 37. Schematic representation of the formation of tribofilm with CuO NPs. 90

Figure 38. The surface profile of plate (a) before sanding (b) after sanding. 91

Figure 39. Roughness parameters comparing before sanding and after sanding of reciprocating plate. 92

Figure 40. The surface profile of wear tracks from (a) 0.05, (b) 0.1, (c) 0.15, and (d) 0.2 wt% CuO NPs concentrations. 93

Figure 41. Roughness parameters comparing all the wear tracks of CuO NPs test runs. 94

Figure 42. XRD spectrum of CuO NBs 95

Figure 43. Raman spectrum of CuO NBs 96

Figure 44. FTIR spectrum of pure CuO NBs 98

Figure 45. FTIR spectrum of CuO NBs nanolubricants 99

Figure 46. (a) SEM image and (b) EDS spectrum of CuO NBs 100

Figure 47. Particle size distribution of CuO NBs 101

Figure 48. (a,b) TEM images of CuO NBs 102

Figure 49. CuO NBs Nanolubricant sedimentation before (a) and after (b) 10 days 102

Figure 50. UV-vis spectra at different CuO NBs concentrations. 104

Figure 51. Time-dependent UV-vis spectra of CuO NBs concentrations 105

Figure 52. Zeta potential of CuO NBs nanolubricants 106

Figure 53. Viscosity increments for different concentrations of CuO NBs. 107

Figure 54. Relative viscosity of CuO NBs concentrations 108

Figure 55. Viscosity index of different concentrations of CuO NBs and pure PAO oil 109

Figure 56. Share Stress vs. share rate for different concentrations of CuO NBs 110

Figure 57. Viscosity vs. share rate for different concentrations of CuO NBs 111

Figure 58. Thermal conductivity for various concentrations of CuO NBs 113

Figure 59. COFs under dry and lubricated conditions without additives 114

Figure 60. COF of base PAO oil vs. COF of PAO oil containing CuO NBs 115

Figure 61. Diagram showing the rolling effect of CuO NBs in lubricating oil. 115

Figure 62. (a)Wear tracks; (b) and (c) track roughness profiles from CuO NBs test runs 117

Figure 63. Roughness parameters of wear tracks from CuO NBs test runs 118

Figure 64. SEM with EDS of wear tracks from CuO NBs test runs: (a) 0.1 wt%; (b) 0.05 wt%; (c) 0.1 wt%; (c) 0.15 wt% 119

Figure 65. Wear rate of all tracks form CuO NBs test runs 121

Figure 66. XRD diffraction of CeO₂ nanoparticles 123

Figure 67. SEM with EDS of CeO₂ nanoparticles 124

Figure 68. TEM morphology of CeO₂ nanoparticles 125

Figure 69. FTIR Spectrum of CeO₂ nanoparticles 126

Figure 70. TG-DTA graph of CeO₂ nanoparticles 127

Figure 71. Newtonian behavior representation in Shear rate vs Shear stress and viscosity of CeO₂ nanolubricants vs PO at different temperatures 130

Figure 72. Relative Viscosity of CeO₂ nanolubricants vs PO 132

Figure 73. Viscosity Index of CeO₂ nanolubricants vs PO 133

Figure 74. Thermal Conductivity of CeO₂ nanolubricants vs PO 134

Figure 75. CoF of all CeO₂ nanolubricant concentrations vs PO 136

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

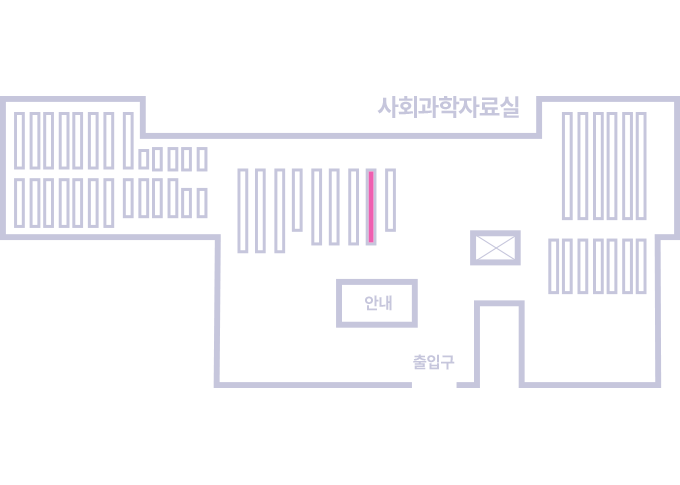

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.