권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

ABSTRACT 9

Ⅰ. 서론 11

1.1. 연구 배경 및 목적 11

1.2. 연구동향 15

1.2.1. 엔진 성능 개선 연구 16

1.2.2. 엔진 주변장치 개선 연구 17

1.2.3. 변속기 개선 연구 18

1.3. 주요 연구대상 19

1) 변속기 어셈블리 (transmission assembly) 19

2) 기어트레인 시스템 (gear/shaft) 19

3) 케이스류 (clutch housing/TM case/rear case) 19

Ⅱ. 이론적 배경 20

2.1. 기어트레인 시스템 평가 방법 20

2.1.1. 기어 강도 평가 20

2.1.2. 기어 손상률 평가 30

2.2. 케이스 형상 최적화 방법 32

Ⅲ. 본론 34

3.1. 시스템 개념설계 34

3.1.1. 성능 요구 조건 분석 34

3.2. 기본설계 36

3.2.1. 파워트레인 운동 성능인자 분석 37

3.2.2. 변속기 내부 기어 경량화에 따른 연비 변화 45

3.3. 설계검증 49

3.3.1. 기어류 구조해석 49

3.3.2. 기어 시스템 구조해석 58

3.3.3. 기어 경량화 및 개선 설계 65

3.3.4. 케이스 구조해석 및 개선 설계안 도출 71

3.3.5. 개선 설계안 연비 상승효과 비교 86

3.4. 상세설계 88

3.5. 시제품 제작 89

3.6. 성능시험 90

3.6.1. 구동 토크 시험 90

3.6.2. 동력전달효율 시험 94

3.6.3. Dynamometer 내구 시험 100

3.6.4. 연비 측정 시험 102

3.7. 실차시험 104

1) 실차시험 방법 104

2) 실차시험 결과 108

3.8. 변속기 장착 전기구동(TMED) 상용차 적용 비교 109

3.8.1. 전기구동 상용차 개요 109

3.8.2. 동력원 선정 및 비교 111

Ⅳ. 결론 115

1) 파워트레인 운동 성능인자 분석 115

2) 다단 자동화 수동변속기 설계 검증 115

3) 다단 자동화 수동변속기 시제품 성능 시험 116

4) 변속기 장착 전기구동 상용차 적용 비교 116

참고문헌 117

Fig. 1.1. Overview of automotive powertrain 11

Fig. 1.2. System sensitivity of powertrain 15

Fig. 2.1. Load of gear tooth 22

Fig. 2.2. Allowable bending stress, sₐₜ 23

Fig. 2.3. Bending strength stress cycle factor, YN[이미지참조] 25

Fig. 2.4. Pitting resistance stress cycle factor, ZN[이미지참조] 25

Fig. 2.5. Allowable contact stress, sac[이미지참조] 27

Fig. 2.6. Hardness ratio factor, CH[이미지참조] 29

Fig. 2.7. Cumulative damage graph in the transmission 31

Fig. 2.8. Design variables a, b, and c for a solid design element 33

Fig. 3.1. Simplified diagram of the planetary gear system(1~6 speed, reverse speed) 39

Fig. 3.2. Simplified diagram of the planetary gear system(7~12 speed) 39

Fig. 3.3. Diagram of the multi-range transmission 40

Fig. 3.4. BSFC of the diesel engine (11,000 cc) 46

Fig. 3.5. Power delivery of 12-speed AMT 50

Fig. 3.6. FEM for gears 51

Fig. 3.7. Boundary conditions for structure analysis 53

Fig. 3.8. Structural analysis of the initial design 56

Fig. 3.9. Modeling of the gear assembly using Romax DESIGNER 60

Fig. 3.10. Result graphs of the 1st main gear 63

Fig. 3.11. Modified modeling for the low gear of the main shaft 66

Fig. 3.12. Modified modeling for the low gear of the counter shaft 66

Fig. 3.13. Structural analysis of the modified design 68

Fig. 3.14. FEA process of transmission cases 72

Fig. 3.15. Specification of size of the 12-speed AMT 72

Fig. 3.16. Load positions of bearing 73

Fig. 3.17. Boundary conditions of the 12-speed AMT case 74

Fig. 3.18. Load conditions of the clutch housing 75

Fig. 3.19. Load conditions of the TM case 75

Fig. 3.20. Load conditions of the rear case 76

Fig. 3.21. The FEA results of the AMT case 79

Fig. 3.22. Shape optimization of the 12-speed AMT 82

Fig. 3.23. The result of shape optimizations 83

Fig. 3.24. The modified cases 83

Fig. 3.25. Structural analysis of the modified model 85

Fig. 3.26. Detail design of the 12-speed AMT 88

Fig. 3.27. Experimental products 89

Fig. 3.28. Test devices for driving torque test 91

Fig. 3.29. The results of the driving torque test for the 12-speed AMT 93

Fig. 3.30. The results of the power transfer efficiency test for the 12-speed AMT 99

Fig. 3.31. Durability test for the 12-speed AMT 101

Fig. 3.32. Test devices for fuel consumption 103

Fig. 3.33. PG(Proving Ground) test 106

Fig. 3.34. Road test 107

Fig. 3.35. The results of PG test and road test 108

Fig. 3.36. Motor efficiency map of the 340 kW motor 112

Fig. 3.37. T-N curve of the 340 kW motor 112

Fig. 3.38. Performance curve of diesel engine in commercial vehicle 113

Trucks carry loads of various weights and require high power. Due to its distinctive characteristics from ordinary passenger cars, Fuel economy and dynamic performance are very important when designing.

The transmission is a very important factor in determining the dynamic performance of a vehicle among various parts of a vehicle, and has a great influence on improving the performance of the vehicle. Therefore transmission design must be considered very important. Design of gears are very complex process that requires consideration of tooth shape, vibration, deformation, and stress. Based on the development know-how, it is difficult to predict the vulnerability for various development requirements in the design by simple experience. Therefore, it is difficult to design an optimal design that satisfies requirements such as weight reduction and compactness.

The existing transmission development process does not go through systematic verification of the basic design due to cost and time issues. This development process leads to numerous failures in the parts development and prototype development stages.

In addition, these failure factors are directly related to the loss of the company, and considerable difficulties arise in securing the required performance established in the system concept design stage. Currently, transmission development companies stays at the low level of simply benchmarking products of advanced overseas companies, and they are having a lot of difficulties in securing their own technology.

In this study, firstly, the factors affecting the power performance from the perspective of a rotating body in an automobile powertrain are investigated. By calculating the mass moment of inertia of the powertrain for each 12-speed, the gears that affect fuel economy are identified. And these use as a basis for the design of weight reduction of gears and shafts.

Secondly, based on the basic design, a systematic design verification using CAE (Computer Aided Engineering) is performed to derive an optimized original design through structural analysis, life analysis, and optimization analysis of major components in the transmission

Thirdly, a performance tests are carried out by mounting the transmission manufactured based on the design plan to secure the reliability of the optimal design.

Lastly, assume that the power source was changed from the existing internal combustion engine power source to an electric motor, the performance of the existing internal combustion engine commercial vehicle and the transmission mounted electric drive (TMED) commercial vehicle are compared.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

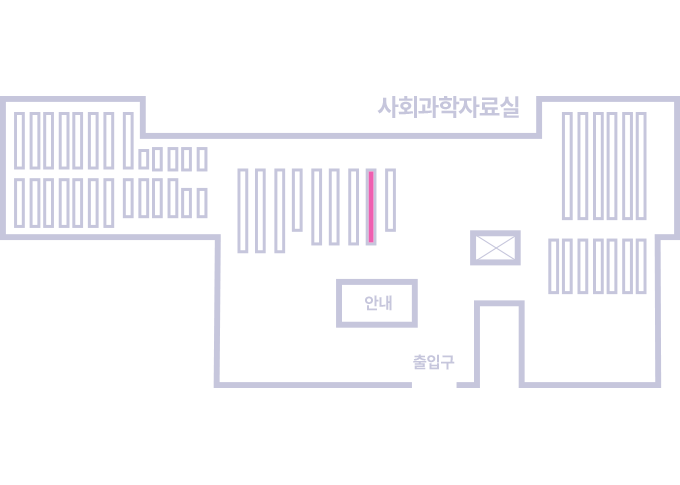

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.