권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

ABSTRACT 8

제1장 서론 10

1.1. 연구 배경 및 목적 10

1.2. 연구 동향 11

제2장 L28/32H 중속 디젤엔진과 연료분사펌프의 개요 13

2.1. L28/32H 중속 디젤엔진의 개요 13

2.2. L28/32H 중속 디젤엔진용 연료분사펌프의 구조 16

2.3. 연료분사펌프의 작동 원리 19

2.4. 컨트롤 랙(control rack)에 의한 연료분사량 조절 20

1) 무분사 상태 20

2) 분사량 조절 20

제3장 연료분사펌프의 제작 및 정밀도 분석 21

3.1. 연료분사펌프 개발 과정 21

3.2. 바렐의 제작 공정 23

3.3. 플런저의 제작 공정 26

3.4. 바렐 및 플런저의 기계적 특성 28

3.5. 연료분사펌프의 정밀 측정 30

3.6. 제품 조립 과정 35

3.7. 연료분사 시스템의 실험 방법 37

3.8. 주요 설계 인자의 정밀도 분석 39

제4장 연료분사펌프의 성능 평가 실험 및 고찰 43

4.1. 성능 평가를 위한 실험 장치 구성 43

4.2. 성능 평가를 위한 실험 방법 47

4.3. 엔진 부하에 따른 분사압력 측정 실험 결과 및 고찰 50

1) 컨트롤 랙 위치 14㎜ (엔진 부하 25%) 50

2) 컨트롤 랙 위치 21mm (엔진 부하 50%) 53

3) 컨트롤 랙 위치 28mm (엔진 부하 70%) 55

4) 컨트롤 랙 위치 35mm (엔진 부하 100%) 57

5) P사 연료분사펌프의 압력 그래프 59

5) N사 연료분사펌프의 압력 그래프 61

4.4. 엔진 부하에 따른 분사량 측정 실험 결과 및 고찰 64

제5장 결론 66

참고문헌 67

Fig. 2-1. Inner section of L28/32H diesel engine made in MDT 15

Fig. 2-2. Assembly parts list of L28/32H fuel injection pump 18

Fig. 2-3. Performance property of fuel injection pump 19

Fig. 2-4. Schematic diagram of injection quantity control by control rack 20

Fig. 3-1. Process for development of product 22

Fig. 3-2. L28/32H fuel injection pump bench marked(left) and 3D modeled(right) 23

Fig. 3-3. Manufacturing process of barrel 24

Fig. 3-4. Manufacturing process of plunger 26

Fig. 3-5. Exploded 3D view of L28/32H fuel injection pump 36

Fig. 3-6. Measurement method for fuel injection pump performance 37

Fig. 3-7. Principal dimension for L28/32H pump element assembly 40

Fig. 4-1. Schematic experimental apparatus of fuel injection pump 43

Fig. 4-2. Drawing of L28/32H fuel injection system tester 45

Fig. 4-3. Drawing of cambox using the L28/32H diesel engine's parts 46

Fig. 4-4. Injection pressure of pump outlet on the engine 25% load 51

Fig. 4-5. Injection pressure of valve inlet on the engine 25% load 52

Fig. 4-6. Injection pressure of pump outlet on the engine 50% load 53

Fig. 4-7. Injection pressure of valve inlet on the engine 50% load 54

Fig. 4-8. Injection pressure of pump outlet on the engine 75% load 55

Fig. 4-9. Injection pressure of valve inlet on the engine 75% load 56

Fig. 4-10. Injection pressure of pump outlet on the engine 100% load 57

Fig. 4-11. Injection pressure of valve inlet on the engine 100% load 58

Fig. 4-12. Injection pressure of fuel injection pump made P corp. 60

Fig. 4-13. Injection pressure of fuel injection pump made N corp. 62

Fig. 4-14. Max. injection pressure compared at the valve inlet 63

Fig. 4-15. Fuel quantity graph of test result 65

Photo 1-1. Damage effect by cavitation in fuel injection pump 12

Photo 2-1. Manufactured fuel injection system of middle speed diesel engine 16

Photo 3-1. Image of a barrel developed according to manufacturing process 25

Photo 3-2. Image of a plunger developed according to manufacturing process 27

Photo 3-3. Special air-micrometer for measurement of barrel 31

Photo 3-4. Special air-micrometer for measurement of plunger 31

Photo 3-5. Cylindricity measurement of barrel & plunger with equipment 33

Photo 3-6. Section dimension of barrel and delivery valve with height gage 34

Photo 3-7. Roughness and shape's measurement of plunger 34

Photo 3-8. Experimental apparatus of L32/40 fuel injection pump 38

Photo 4-1. Experimental apparatus for L28/32H fuel injection pump 44

Photo 4-2. Measuring cylinder for measurement of injection quantity 49

Photo 4-3. Sensor for measurement of pressure in high pressure pipe 49

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

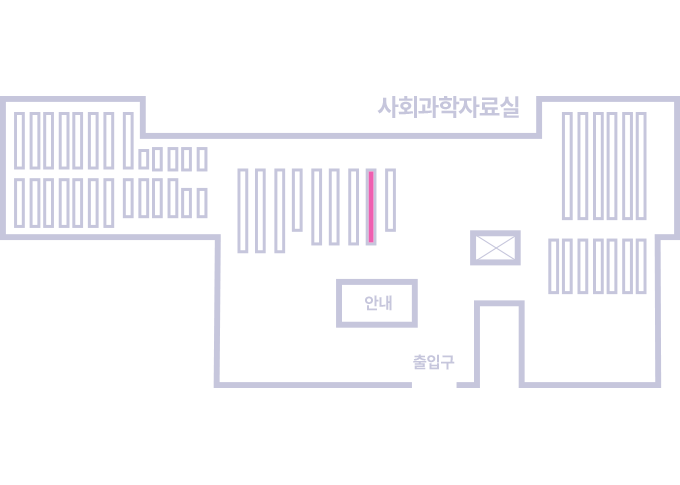

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.