권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

Title Page

ABSTRACT

Contents

1. Introduction 11

2. Backgrounds 13

2.1. Gallium Arsenide (GaAs) for spintronics 13

2.2. Surface defects in GaAs growth 16

2.2.1. Mound shape defects 16

2.2.2. Triangle shape defects 19

2.3. How to suppress the surface defects? 21

2.3.1. Growth temperature and Ga/As flux ratio 21

2.3.2. Vicinal substrates 24

3. Experimental 26

3.1. Basic concept of molecular beam epitaxy 26

3.2. Epitaxial growth of GaAs(110) 30

3.3. Surface morphology analysis 32

3.4. Microstructure analysis 33

4. Results and Discussion 35

4.1. An effect of a layer thickness on the GaAs(110) layer 35

4.1.1. An observation of surface morphology evolution 35

4.1.2. An observation of the Ga or As agglomeration 42

4.1.3. An observation of underlying crystal defects 43

4.2. An effect of a growth temperature on the GaAs(110) layer 51

5. Conclusions 54

References 56

Fig. 1. Schematic of gallium arsenide structure. 13

Fig. 2. Atomic arrangement of the surfaces (a) GaAs(001) and (b) GaAs(110). 15

Fig. 3. Surface and underlying defects in GaAs(001) called "mound (a)" and "pyramid (b)" respectively. 17

Fig. 4. Schematic of Ehrlich-Schwoebel barrier energy to inhibit downward movement of adatoms. 18

Fig. 5. 5 Reported triangle shaped surface defects (a) and〈112〉directional step edge (b). 20

Fig. 6. AFM image of a 1,000 ㎚ thick GaAs(001) layer grown at a substrate temperature of (a) 280 ℃ and (b) 210 ℃. 22

Fig. 7. Normarski microscopic images (90 ㎛ × 90 ㎛) of the GaAs(110) surface after deposition 1000ML of GaAs at five different growth conditions using As₄.... 23

Fig. 8. Schematic of the islands formation mechanism on the relatively longer terrace of the GaAs surface. 24

Fig. 9. Cross-sectional electron microscopy bright field images of LT-GaAs layers on different substrate types (a) nominal substrate and (b) vicinal substrate. 25

Fig. 10. Schematic of a typical MBE system. 26

Fig. 11. Mechanisms of RHEED intensity oscillations during growth of a monolayer. 28

Fig. 12. 12 Different surface elemental processes occurring in MBE growths. 29

Fig. 13. Schematic of homoepitaxial GaAs(110) growth process and conditions. 31

Fig. 14. Schematic of AFM instrument showing "beam bounce" method of detection using a laser and position sensitive photodiode detector. 32

Fig. 15. Interactions between electrons and material. 33

Fig. 16. Schematic illustration of cross-sectional TEM sampling to be have [110] zone axis using a FIB to investigate the crystal defects in GaAs(110) layer.(이미지참조) 34

Fig. 17. 10 ㎛ × 10 ㎛ AFM images (a)-(e) of GaAs(110) surface depending on different layer thickness (a) 200 ㎚, (b) 300 ㎚, (c) 350 ㎚, (d) 500 ㎚, and (e)... 36

Fig. 18. AFM image of elongated line defects along with [110] on the surface.(이미지참조) 38

Fig. 19. (a) measured roughness data of surface defects by AFM analysis, (b) height, and (c) size (length × width). 40

Fig. 20. 20 Scanning electron microscopy images with different layer thickness (a) 200 ㎚, (b) 300 ㎚, (c) 500 ㎚, and (d) 1,000 ㎚ (Insets are AFM images observed). 41

Fig. 21. Electron probe micro-analyzer results (a) SEM image, (b) Ga distribution, and (c) As distribution. 42

Fig. 22. (a) SEM and (b) cross-sectional TEM images sampled by FIB 44

Fig. 23. Comparison of twin density between (a) out of pyramid region and (b) inner pyramid region. 45

Fig. 24. Cross-sectional TEM image and diffraction patterns of GaAs(110) substrate and homoepitaxial layer in [110] zone axis (a) TEM image, (b) substrate...(이미지참조) 46

Fig. 25. (a) cross-sectional TEM image and diffraction patterns for three different regions (b) region 1 (between long legs), (c) region 2 (out of pyramid), and (d)... 47

Fig. 26. Illustration of stacking fault formation in zinc-blende structure (a) zinc-blende (111) surface, (b) wurtzite(0001) surface, and (c) inserted wurtzite 1... 48

Fig. 27. (a) cross-sectional TEM image and (b) Balls and sticks model of the pyramid defect formation in GaAs(110). 49

Fig. 28. Cross-sectional TEM images and diffraction patterns of long leg (a) TEM image, (b) HRTEM image, (c) FFT image out of long leg, and (d) FFT image of... 50

Fig. 29. 10 ㎛ × 10 ㎛ AFM images (a)-(e) of GaAs(110) surface depending on different growth temperature (a) 360 ℃, (b) 400 ℃ , (c) 420 ℃, (d) 440 ℃, and... 53

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

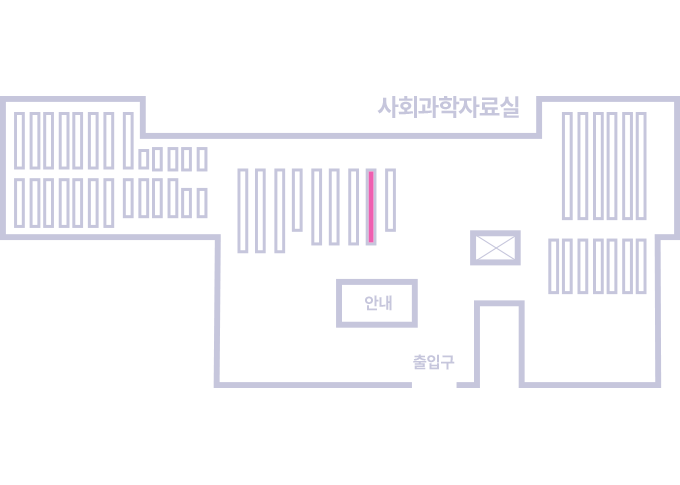

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.