권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

Abstract 9

I. 서론 11

II. 이론적 고찰 14

1. 점증제 첨가량에 따른 발포금속의 제조 특성 14

2. 발포 온도와 냉각속도에 따른 제조 특성 변화 15

3. 발포금속의 기계적 특성 16

III. 실험 방법 18

1. 606X계 합금의 발포 분석 18

2. 기공의 조직관찰 23

3. 밀도, 기공율 및 기공크기 측정 23

4. 압축강도, 에너지 흡수량 및 경도 측정 24

IV. 실험결과 및 고찰 25

1. 6061 합금 발포금속의 점증제 첨가량과 온도의 영향 25

2. 6061 합금 발포금속의 발포제 첨가 온도와 냉각속도의 영향 30

3. 6063 합금 발포금속의 발포제 첨가 온도와 냉각속도의 영향 35

4. 발포 기공과 기공벽의 미세조직 및 기공율 측정 40

5. 606X계 합금 발포금속의 압축특성 47

V. 결론 54

참고문헌 56

감사의 글 59

Fig. 1. The compressive stress-strain curves for pure aluminum foams. 17

Fig. 2. Schematic diagram of apparatus for making metallic foams: (1) stirrer (2) mixing furnace, (3) holding furnace. 21

Fig. 3. Experimental flow chart for fabrication of metallic foams. 22

Fig. 4. Macrostructure of pure aluminum foams with different calcium content at stirring time for 20 min. (a) 0.5 wt.% Ca, (b) 1.0 wt.% Ca, (c)1.5 wt.% Ca, (d) 2.0 wt.% Ca. 27

Fig. 5. The representative 6061 aluminum alloy metallic foam specimens foamed at 680℃ with addition of (a) 1wt.% Ca, (b) 1.5wt.% Ca and (c) 2wt.% Ca. 28

Fig. 6. The representative 6061 aluminum alloy metallic foam specimens which foamed at (a) 680℃, (b) 730℃ and (c) 780℃. 29

Fig. 7. The representative 6061 aluminum alloy metallic foam specimens foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680℃ and (b) 730 ℃ with water cooling. 31

Fig. 8. Macroscopic view of the 6061 aluminum alloy foams which foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680℃ and (b) 730℃ with water cooling. 33

Fig. 9. The cell size distribution of 6061 aluminum alloy metallic foam with air and water cooling. 34

Fig. 10. The representative 6063 aluminum alloy metallic foam specimens foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680℃ and (d) 730℃ with water cooling. 37

Fig. 11. Macroscopic view of the representative 6063 aluminum alloy metallic foam specimens foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680℃ and (d) 730℃ with water cooling 38

Fig. 12. The cell size distribution of 6063 aluminum alloy metallic foam with air and water cooling. 39

Fig. 13. Microstructure of AA6061 metallic foam specimens which foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680°C and (d) 730℃ with water cooling. 43

Fig. 14. Microstructure of AA6063 metallic foam specimens which foamed at (a) 680℃ and (b) 730℃ with air cooling and (c) 680℃ and (d) 730℃ with water cooling. 44

Fig. 15. Second electron microscopy of 6061 and 6063 aluminum alloy metallic foams with different cooling conditions; (A) Al 6061, Air cooling, (B) Al 6061. Water cooling (C) Al 6063, Air cooling, (D) Al 6063, Water cooling. 45

Fig. 16. Comparison of morphological features for 6061 and 6063 aluminum alloy metallic foams with different foaming and cooling conditions; (A) 680℃, Air cooling (B) 730℃, Air cooling (C) 680℃, water cooling (D) 730℃, water cooling 46

Fig. 17. The compressive stress-strain curves for the 6061 aluminum alloy metallic foams with different foaming temperature and cooling rate. 50

Fig. 18. The compressive stress-strain curves for the 6063 aluminum alloy metallic foams with different foaming temperature and cooling rate. 51

Fig. 19. Comparison of Vickers hardness of 606X aluminum alloy metallic foams with different foaming and cooling conditions; (A) Al 6061, foamed at 680℃ (B) Al 6061, foamed at 730℃ (C) Al 6063, foamed at 680℃ (D) Al 6063, foamed at 730℃ 53

Metal foam is one of the most interesting materials in the field of functional materials. However, due to its various special properties such as super light weight, good energy absorption, high stiffness and outstanding damping capability, it has already become known as one of the most smart applicable material for many structural and functional uses in such various fields of automotives, transports, ships and aerospace applications. Particularly Al-foam filled composite materials are widely being considered these days for structural use in aircrafts and satellites, and also functional use in automotive bumpers, roofs and door beams for improving the crash-worthiness of vehicles which will ultimately reduce the damage of the vehicles and increase safety of the passengers during crushing. Industrial production of foamed metals is now established for applications like sandwich structures, panels, foam-filled crash absorbers, heat exchangers and so on.

In present research, especially, aluminum alloy metallic foams which has various compressive strength to apply to foam-filled crash absorber is fabricated. and its mechanical properties were evaluated. Commonly, it is known that compression strength of the metal foam is related with density and cell size of metal foam. However, it is difficult to control them. Because complex thermal distribution of melt that caused by both of metal melt and air bubbles. In present research, however, heat treatable matrix material, 606X series aluminum alloy foam which is widely used in automotive and for architecture is introduced. And evaluate the improvement of compression strength by comparison study with pure aluminum metallic foam.

Aluminum alloy including 6061 and 6063 aluminum alloy foams were prepared by down sprue foam casting method as follow steps. Individual Ca containing molten aluminum alloy was mechanically stirred. Then TiH₂ is introduced in the molten aluminum alloy and subjected to subsequent stirring at 1000 rpm for 30 sec. Finally individually treated melt were poured into holding furnace at 680℃, 730℃ and 780℃. To controlling pore structure, quenching rates is regulated and measured by real-time measuring system. Compression strength and vickers hardness was also measured to evaluate the mechanical properties for energy absorbing materials. and it is compared with structural features by measured and calculated values of cell structure, cell size distribution and porosity.

Compression strength of various samples is increased with increasing foaming temperature and cooling rate. This is because of increasing of density and cell wall thickness caused by high cooling rate and low melt viscosity.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

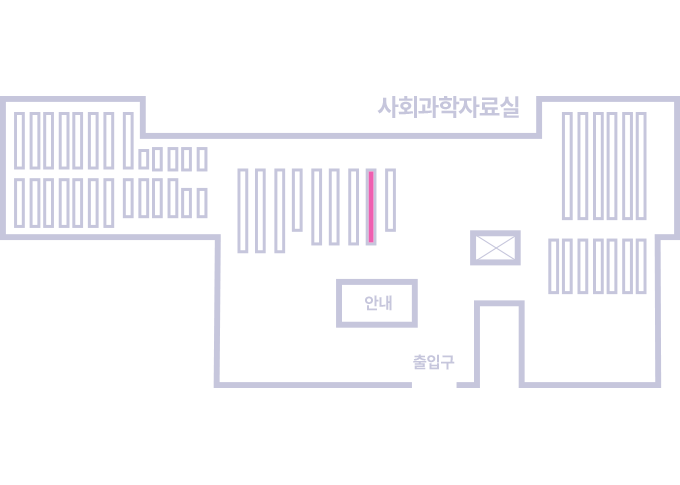

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.