권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

| 기사명 | 저자명 | 페이지 | 원문 | 목차 |

|---|---|---|---|---|

| 단일레인 듀얼로봇 물류시스템의 성능분석 모형 = Analytical model to evaluate the performance of single-lane dual-robot material handling system | 정재우 | p. 1-14 |

|

|

| 반도체 FAB에서 웨이퍼 로트 적기운반을 위한 재공 저장 위치 선정 연구 = A WIP allocation approach for enhancing on-time transfers of wafer lots in a semiconductor fabrication facility | 김해중, 이종성 | p. 47-55 |

|

|

| 직배송 전략에서 탄소 배출 제약들을 고려한 최적의 배송량 및 탄소 저감 투자 결정 = Optimal lot size and reduction investment with carbon emission constraints under direct shipment strategy | 류종현, 정광헌 | p. 31-45 |

|

|

| 수소경제에서 연료전지발전의 역할 = Role of fuel cell power plant in hydrogen economy | 정용주 | p. 15-29 |

| 번호 | 참고문헌 | 국회도서관 소장유무 |

|---|---|---|

| 1 | Ahn, K., and Park, J.(2019), “Idle vehicle rebalancing in semiconductor fabrication using factorized graph neural network reinforcement learning,” Proceedings of the IEEE Conference on Decision and Control, 2019-December, 132-138. | 미소장 |

| 2 | Bahri, N., Reiss, J., and Doherty, B.(2001), "A comparison of unified vs. segregated automated material handling systems for 300 mm fabs,”2001 IEEE International Symposium on Semiconductor Manufacturing. ISSM 2001. Conference Proceedings (Cat. No.01CH37203), San Jose, CA, USA, 2001, 3-6 | 미소장 |

| 3 | Bartlett, K., Lee, J., Ahmed, S., Nemhauser, G., Sokol, J., and Na, B.(2014), “Congestionaware dynamic routing in automated material handling systems.” Computers and Industrial Engineering, 70(1), 176-182. | 미소장 |

| 4 | Bozer, Y.A., and Yen, C.K.(1996), “Intelligent dispatching rules for trip-based material handling systems,” Journal of Manufacturing Systems, 15(4), 226-239. | 미소장 |

| 5 | Chaabane, A.B, Dauzere-Peres, S., Yugma, C., Rulliere, L., and Lamiable, G.(2013), “Analyzing the impact of key parameters of vehicle management policies in a unified AMHS,” 2013Winter Simulations Conference, 3818-3828. | 미소장 |

| 6 | Chen, T.J., Sun, Y., Dai, W., Tao, W., and Liu, S.(2013), “On the shortest and conflict-free path planning of multi-AGV system based on dijkstra algorithm and the dynamic time-window method,” Advanced Materials Research, 645, 267-271. | 미소장 |

| 7 | de Koster, R.M.B., Le-Anh, T., and van der Meer, J.R.(2004), “Testing and classifying vehicle dispatching rules in three real-world settings,”Journal of Operations Management, 22(4), 369-386. | 미소장 |

| 8 | Egbelu, P.J.(1987), “Pull versus push strategy for automated guided vehicle load movement in a batch manufacturing system,” Journal of Manufacturing Systems, 6(3), 209-221. | 미소장 |

| 9 | Huang, C.-J., Chang, K.-H., and Lin, J.T.(2012), “Optimal vehicle allocation for an automated materials handling system using simulation optimisation,”International Journal of Production Research, 50(20), 5734-5746. | 미소장 |

| 10 | Kiba, J., Dauzère-Pérès, S., Yugma, C., and Lamiable, G.(2010), “Comparing transport policies in a full-scale 300mm wafer manufacturing facility,”Progress in Material Handling Research. | 미소장 |

| 11 | Kim, B.I., and Park, J.(2009), “Idle vehicle circulation policies in a semiconductor FAB,” Journal of Intelligent Manufacturing, 20(6), 709-717. | 미소장 |

| 12 | Kim, B.-I., Oh, S., Shin, J., Jung, M., Chae, J., and Lee, S.(2007), “Effectiveness of vehicle reassignment in a large-scale overhead hoist transport system,” International Journal of Production Research, 45(4), 789-802. | 미소장 |

| 13 | Kim, C.W., Tanchoco, J.M.A., and Koo, P.H. (1999), “AGV dispatching based on workload balancing,” International Journal of Production Research, 37(17), 4053-4066. | 미소장 |

| 14 | Kim, C.W., and Tanchoco, J.M.A.(1991), “Conflict-free shortest-time bidirectional AGV routeing,”International Journal of Production Research, 29(12), 2377-2391. | 미소장 |

| 15 | Kim, H., Lim, D.E., and Lee, S.(2020), “Deep learning-based dynamic scheduling for semiconductor manufacturing with high uncertainty of automated material handling system capability,” IEEE Transactions on Semiconductor Manufacturing, 33(1), 13-22. | 미소장 |

| 16 | Kuo, C.-H., and Huang, C.-S.(2006), “Dispatching of overhead hoist vehicles in a fab intrabay using a multimission-oriented controller,”The International Journal of Advanced Manufacturing Technology, 27(7-8), 824-832. | 미소장 |

| 17 | Lau, H.Y.K., and Woo, S.O.(2008), “An agent based dynamic routing strategy for automated material handling systems,” International Journal of Computer Integrated Manufacturing, 21(3), 269-288. | 미소장 |

| 18 | Le-Anh, T., and De Koster, M.B.M.(2005), “On-line dispatching rules for vehicle-based internal transport systems,” International Journal of Production Research, 43(8), 1711-1728. | 미소장 |

| 19 | Lee, S., Kim, H.J., and Kim, S.B.(2020), “Dynamic dispatching system using a deep denoising autoencoder for semiconductor manufacturing,”Applied Soft Computing Journal, 86, 105904. | 미소장 |

| 20 | Lee, S., Lim, D.E., Kang, Y., and Kim, H.J. (2021), “Clustered Multi-Task Sequence-to-Sequence Learning for Autonomous Vehicle Repositioning,”IEEE Access, 9. | 미소장 |

| 21 | Liao, D.-Y., and Fu, H.-S.(2004), “Speedy delivery - dynamic OHT allocation and dispatching in large-scale, 300-mm AMHS management,”IEEE Robotics & Automation Magazine, 11(3), 22-32. | 미소장 |

| 22 | Lin, J.T., Wu, C.H., and Huang, C.W.(2013), “Dynamic vehicle allocation control for automated material handling system in semiconductor manufacturing,” Computers and Operations Research, 40(10), 2329-2339. | 미소장 |

| 23 | Min, H.-S., and Yih, Y.(2003), “Selection of dispatching rules on multiple dispatching decision points in real-time scheduling of a semiconductor wafer fabrication system,” International Journal of Production Research, 41(16), 3921-3941. | 미소장 |

| 24 | Siebert, M., Bartlett, K., Kim, H., Ahmed, S., Lee, J., Nazzal, D., … Sokol, J.(2018), “Lot targeting and lot dispatching decision policies for semiconductor manufacturing: optimisation under uncertainty with simulation validation,”International Journal of Production Research, 56(1-2), 629-641. | 미소장 |

| 25 | Smolic-Rocak, N., Bogdan, S., Kovacic, Z., and Petrovic, T.(2010), “Time windows based dynamic routing in multi-AGV systems,” IEEE Transactions on Automation Science and Engineering, 7(1), 151-155. | 미소장 |

| 26 | Taghaboni-Dutta, F., and Tanchoco, J.M.A. (1995), “Comparison of dynamic routeing techniques for automated guided vehicle system,”International Journal of Production Research, 33(10), 2653-2669. | 미소장 |

| 27 | Vahdani, B.(2014), “Vehicle positioning in cell manufacturing systems via robust optimization,”Applied Soft Computing Journal, 24, 78-85. | 미소장 |

| 28 | Wang, F.K., and Lin, J.T.(2004), “Performance evaluation of an automated material handling system for a wafer fab,” Robotics and Computer-Integrated Manufacturing, 20(2), 91-100. | 미소장 |

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

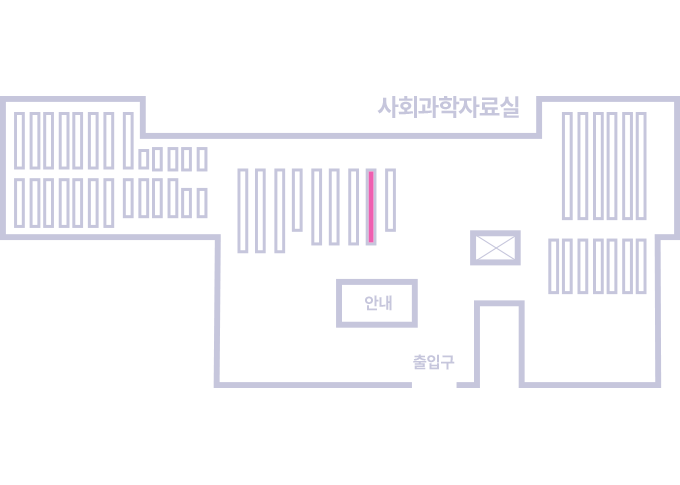

도서위치안내: 정기간행물실(524호) / 서가번호: 국내01

2021년 이전 정기간행물은 온라인 신청(원문 구축 자료는 원문 이용)

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.