권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

Title Page

Contents

ABSTRACT 8

Ⅰ. INTRODUCTION 10

Ⅱ. BACKGROUND 12

1. Consumer-level 3D Printer 12

2. Abuse Cases of 3D Prints 14

3. Printer Characterization Factors 16

1) Pattern noise 16

2) Random noise 17

Ⅲ. DATASET 18

1. PreParation 18

2. Collect 3D Prints 19

3. Digital capture of 3D prints 22

1) Close-up image acquisition 22

2) Full object image acquisition 23

Ⅳ. SOURCE IDENTIFICATION TASKS 26

1. Printer Model Identification 27

2. Filament Material Identification 27

3. Quality Parameter Identification 28

4. Device-level Identification 28

5. Scan-and-reprint Detection 29

Ⅴ. EXPERIMENTAL SETUP 30

1. Evaluation protocol 30

A. Select data type 30

B. Separation of data for cross-validation 30

C. Evaluation per task 31

2. Proposed approach 31

Ⅵ. RESULTS 34

1. Comparison test 36

2. Impact of Different Geometries 37

3. Printer Model Identification 38

4. Filament Matrial Identification 39

5. Quality Parameter Identification 40

6. Device-level Identification 41

7. Scan-and-reprint Detection. 43

8. Printer Fingerprint matching 44

Ⅶ. DISCUSSION AND CONCLUSION 46

Ⅷ. REFERENCES 48

Abstract 55

Figure 1. Example of abuse cases of 3D Prints: (a) unauthorized 3D printed firearm production [48], (b) fingerprint generation [6], (c) illegal distribution... 15

Figure 2. Fabricated 3D objects for our dataset 21

Figure 3. Data samples from the 3DP dataset. 23

Figure 4. Samples of close-up images for (top) filament type verses quality parameter, and (down) texture type. 24

Figure 5. 3DP close-up image statistics. (left to right) filament, printer model, object model, and quality type. 25

Figure 6. Schematic illustration of the proposed baseline approach. 33

Figure 7. (a) Evaluation results by varying the ensemble ratio of close-up image and full object image, (b) the overall precision by varying the... 35

Figure 8. Printer model identification results based on, (a) close-up image dataset, and (b) full object image. 38

Figure 9. Filament material identification results based on, (a) close-up image dataset, and (b) full object image. 39

Figure 10. Confusion matrix of device-level identification: (a) objective: D, image: sc, (b) objective: D+P, image: sc+sf.[이미지참조] 42

Figure 11. Histogram of feature distances. Lower value implies the same printer model. 45

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

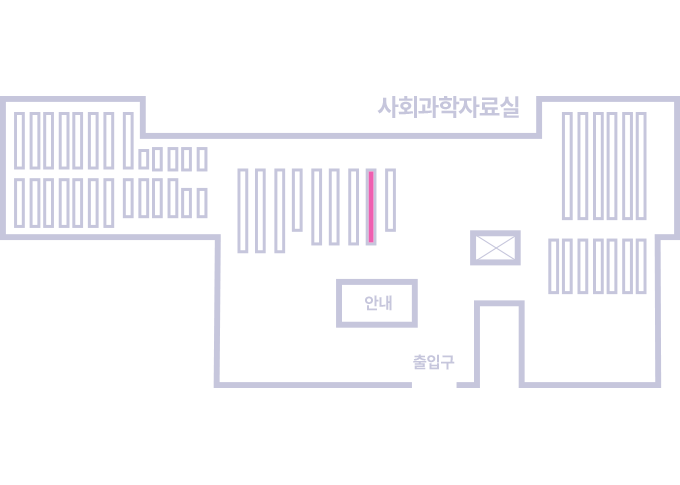

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.