권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

국문 초록

목차

1. 서론 17

1.1. 연구 배경 및 목적 17

1.2. 연구내용 및 구성 18

2. 이론적 배경 20

2.1. 전자폐수 증가 추세 20

2.2. 전자 폐수의 일반적 특성 21

2.3. 반도체 제조 공정 23

2.3.1. 식각폐수의 발생 25

2.4. 불소의 독성 27

2.4.1. 불소(Fluorine) 27

2.4.2. 생체에 미치는 영향 28

2.4.3. 불화수소(HF, hydrogen fluoride) 29

2.5. 응집·침전 이론 30

2.5.1. 응집의 정의 30

2.5.2. 입자의 안정화 특성 31

2.5.3. 입자의 불안정화 원리 35

2.5.4. 응집제를 이용한 응집 40

2.5.5. 응집의 영향 인자 42

2.6. 불산 폐수처리 44

2.6.1. 불소 제거 방법 44

2.6.2. 전자제품 산업 불산폐수 처리 51

2.7. 응집제의 종류 52

2.7.1. 소석회(Calcium hydroxide) 52

2.7.2. PACl(Poly-aluminum chloride) 54

2.8. 법적 규제 변화 55

3. 연구 방법 58

3.1. 실험방법 및 분석방법 58

3.1.1. 처리 대상 불산 폐수 시료 61

3.1.2. 약품 선정 61

3.1.3. Jar-test 64

3.1.4. 분석 방법 64

3.2. 기존 불산폐수 불소제거 공정 65

3.2.1. 1차 처리 66

3.2.2. 2차 처리 66

3.3. 별도 pH 조정제 투입을 통한 개선 공정 실험 67

3.3.1. 1차 처리 68

3.3.2. 2차 처리 68

4. 실험결과 및 고찰 70

4.1. 기존 불산폐수 불소제거 공정 70

4.1.1. 1차 처리 - 1단계(소석회) 70

4.1.2. 1차 처리 - 2단계(PACl) 73

4.1.3. 2차 처리(PACl→소석회) 75

4.2. 별도 pH조정제 투입을 통한 공정개선 방안 80

4.2.1. 1차 처리(소석회+pH조정제) 80

4.2.2. 2차 처리(PACl+pH조정제) 83

5. 결론 96

References 99

ABSTRACT 107

Figure 2.1. Wastewater Generation and Discharge Status by Industry Classification 20

Figure 2.2. Wastewater Discharge and Treatment Flow in the Semiconductor Wafer Processing Procedure 24

Figure 2.3. (a) Stable particles and (b) Unstable particles 31

Figure 2.4. Schematic of electrical double layer at solid-liquid interface 33

Figure 2.5. Schematic of double layer (a) Effect of increasing concentration of indifferent electrolyte, (b) Reversal of... 34

Figure 2.6. Equilibrium composition of solutions in contact with freshly precipitated Al(OH)₃ and Fe(OH)₃ 42

Figure 2.7. Relationship between pH and the distribution of soluble aluminum species 47

Figure 2.8. Hydrofluoric acid wastewater treatment(Best Available Techniques Reference Document) 51

Figure 3.1. Existing hydrofluoric acid wastewater treatment process 58

Figure 3.2. Improved hydrofluoric acid wastewater treatment process 59

Figure 3.3. Existing hydrofluoric acid wastewater treatment process - 1st Treatment[이미지참조] 66

Figure 3.4. Existing hydrofluoric acid wastewater treatment process - 2nd Treatment[이미지참조] 67

Figure 3.5. Improved hydrofluoric acid wastewater treatment process - 1st Treatment[이미지참조] 68

Figure 3.6. Improved hydrofluoric acid wastewater treatment process - 2nd Treatment[이미지참조] 69

Figure 4.1. Correlation between Ca(OH)₂ concentration and pH 71

Figure 4.2. Concentration of F and T-P over Ca(OH)₂ Concentration with New Optimal pH Range for F Removal 72

Figure 4.3. Correlation between PACl concentration and pH 74

Figure 4.4. Concentration of F and T-P over PACl Concentration in 1st Treatment[이미지참조] 75

Figure 4.5. Variation in Ca(OH)₂ Concentration with PACl Injection Concentration under Neutral pH Conditions 77

Figure 4.6. Concentration of F and T-P over PACl Concentration in 2nd Treatment[이미지참조] 78

Figure 4.7. Concentration of Chloride over PACl Concentration in Existing process 79

Figure 4.8. SVI over PACl Concentration in Existing process 80

Figure 4.9. Concentration of F and T-P over pH in Advanced treatment process 83

Figure 4.10. Concentration of F and T-P over PACl in Advanced treatment process(pH 11.1) 85

Figure 4.11. Concentration of F and T-P over PACl in Advanced treatment process(pH 10.45) 86

Figure 4.12. Concentration of F and T-P over PACl in Advanced treatment process(pH 10.04) 87

Figure 4.13. Concentration of F and TP over PACl in Advanced treatment process(pH 9.55) 89

Figure 4.14. Concentration of Chloride over PACl Concentration in Improved process 91

Figure 4.15. SVI over PACl Concentration in Improved process 92

Figure 4.16. Concentration of Sulfate over PACl Concentration in Improved process 93

반도체 및 디스플레이를 비롯한 다양한 전자제품 제조업체 사업장에서는 제품을 생산하는 과정에서 다양한 화학물질을 사용하며, 이로 인해 많은 양의 폐수를 배출하고 있다. 더욱이 반도체 제조공정의 기술적 고도화에 따라 화학약품의 사용량 및 폐수의 발생량은 지속적으로 증가하는 추세를 보이고 있다. 이러한 현상은 환경적 관점에서 주요한 이슈로 부상하고 있으며, 해당 산업 분야에서 지속 가능한 발전을 추구하는 데 있어 중대한 고려 요소로 자리매김하고 있다.

이러한 전자 폐수는 다양한 화학물질과 함께 고농도의 불소를 포함하고 있으며, 이는 적절한 처리 절차를 거치지 않을 경우 심각한 환경오염과 인체 건강에 대한 위협을 야기할 수 있다. 특히, 불소는 지하수나 토양에 침투하여 장기간 축적되면서 생태계 및 인체에 심각한 영향을 끼치는 특성을 지니고 있다. 이에 따라, 반도체 폐수에서 불소를 효과적으로 제거할 수 있는 기술 개발은 환경 보호와 공중 보건의 관점에서 매우 중대한 과제로 인식되고 있다.

비교적 경제성이 높고 수급이 용이한 Ca(OH)₂(소석회) 및 PACl(Polyaluminum chloride)와 같은 응집제를 활용한 불소 처리 기술은 전자 폐수 처리 공정에 광범위하게 적용되고 있다. 이러한 기술은 적절한 pH 조건에서 구현될 때 최적의 불소 제거 효율을 달성할 수 있으며, 이는 환경 보호와 비용 효율성의 균형을 맞추는 데 중요한 역할을 한다.

본 연구에서는 불소 제거 공정에서 기존의 방식과는 다른 pH 조정 방법을 적용하여 소석회 및 PACl을 이용한 전자 폐수 내 불소처리에 대한 실험을 수행하고, 이를 기반으로 해당 기술의 처리 효율과 적용 가능성에 대해 검토하고자 하였다.

이를 위해 우선적으로 기존의 처리방식, 즉 별도의 pH 조정제를 적용하지 않은 상태에서 전자 폐수 내 불소 제거 실험을 진행하였다. 이후, 새롭게 제시된 공정, 즉 별도의 pH 조정제를 주입하는 공정을 적용한 실험을 추가로 수행하였다.

두 가지 실험 결과를 바탕으로 기존 공정과 신규 공정의 처리 효율을 비교 분석함으로써 불소처리 기술의 최적화 방안을 모색하였다. 그 결과, 별도의 pH 조정제 주입을 통해 1차 처리 과정에서의 침전 효율 향상과 2차 처리 과정에서의 반응 효율 개선을 확인하였다. 이러한 개선 효과는 약품 사용량 저감 및 불소 제거 효율 향상의 실험 결과를 수치화하여 정량적으로 확인하였다.

본 연구를 통해 환경오염과 인체 건강에 미치는 위험성이 높은 전자 폐수 내 불소를 효과적으로 제거할 수 있는 기술 개발에 기여하고 전자산업으로 인한 폐수 문제에 대해 지속 가능한 해결책을 제시하고자 하였으며, 이 연구 결과는 환경 관리 및 공중 보건 개선 측면에서도 긍정적인 영향을 미칠 것으로 기대된다.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

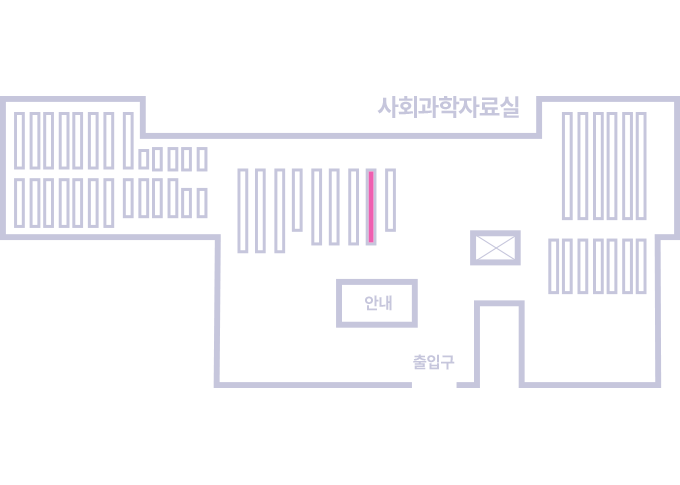

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.