권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

Title Page

Contents

SYMBOLS AND ABBREVATIONS 10

VITA 13

PUBLICATIONS 14

ABSTRACT 15

CHAPTER 1. INTRODUCTION 17

1.1. Introduction 18

1.1.1. Water-soluble polymers and applications 18

1.1.2. Cellulose and cellulose derivatives 21

1.1.3. Characteristics of HPMC and applications 24

1.2. Organization of dissertation 29

CHAPTER 2. HPMC-BASED HYDROGEL AS A TRANSDERMAL DRUG DELIVERY SYSTEM IN COSMECEUTICAL FIELDS 30

2.1. Introduction 31

2.2. Materials and methods 35

2.2.1. Reagents and materials 35

2.2.2. Preparation of hydrogel 36

2.2.3. Morphological characterization of hydrogel 38

2.2.4. Analysis of physico-chemical properties 38

2.3. Results and discussion 39

2.3.1. Morphological characteristics of HPMC based hydrogel 39

2.3.2. Control of hydrogel physico-chemical factors 41

2.3.3. Release profile of niacinamide from hydrogels 43

2.3.4. Composition optimizes 45

2.4. Conclusion 46

CHAPTER 3. ENHANCED SOLUBILITY THROUGH PARTICLE SIZE CONTROL, MODIFICATION OF CRYSTAL BEHAVIOR, AND CRYSTALLINE FORM CHANGES IN SOLID DISPERSION OF NIFEDIPINE 48

3.1. Introduction 49

3.2. Materials and methods 53

3.2.1. Reagents and materials 53

3.2.2. Solid dispersion preparation 53

3.2.3. Morphological characterization of solid dispersion 56

3.2.4. Crystallinity analysis 56

3.2.5. Drug release rate measurement 57

3.3. Results and discussion 58

3.3.1. Morphological characteristics of solid dispersions 58

3.3.2. Crystallographic analysis of solid dispersions 60

3.3.3. Drug release behavior of nifedipine 66

3.4. Conclusion 69

CHAPTER 4. CONCLUSION AND FUTURE WORKS 70

4.1.1. Conclusions 71

4.1.2. Future works 72

REFERENCES 74

Figure 1-1. Wood products and application of cellulose 22

Figure 1-2. HPMC structure and process according to viscosity 25

Figure 2-3. Applications of cellulose-based hydrogels 32

Figure 2-4. HPMC-based hydrogel as a transdermal drug delivery system for active ingredients 33

Figure 2-5. The chemical formula of the niacinamide as an active ingredient. 35

Figure 2-6. Simplex design plot by mixture design with HPMC, algae extract (Carrageenan) and gum additive (LBG). 36

Figure 2-7. Analytical methods for investigating physico-chemical properties of hydrogel samples (A) Texture analyzer (B) Franz diffusion cell system 39

Figure 2-8. SEM analysis of hydrogel S7 and Competitor 40

Figure 2-9. Gel hardness (GH) and elongation(E) of hydrogels 41

Figure 2-10. Gel adhesive force (GAF) of hydrogels 42

Figure 2-11. Release profile of the active ingredient(niacinamide) from hydrogels 44

Figure 2-12. Cox reaction trajectory and overlaid contour plots regarding GH, GAF, ESR 45

Figure 3-13. Preparation method of solid dispersions 50

Figure 3-14. Examples of spray dried therapeutics 50

Figure 3-15. The chemical structure of nifedipine 51

Figure 3-16. Scheme of the spray-drying manufacturing method: Feed ①, Spray-drying chamber ②, Separating ③, and Spray-dried product ④. 54

Figure 3-17. Particle forms of nifedipine raw material and solid dispersions containing various polymers. (A) Nifedipine, (B) PVP, (C) Eudragit E100, (D)... 59

Figure 3-18. X-ray diffraction graph of solid dispersions containing nifedipine raw materials and polymers. (A) Nifedipine (yellow), PVP (dark blue),... 65

Figure 3-19. Drug release rate of nifedipine raw material and polymer-containing solid dispersions. Graph shows dissolution results for nifedipine raw... 68

HPMC is the most widely used cellulose-based polymer, and its properties vary depending on the ratio of methoxy and hydroxypropyl substitution. Accordingly, the uses for each dosage form are also varied, and they are generally used as binders, coating agents, or film formers in the manufacture of tablets or granules of oral dosage forms. In particular, in recent years, it has been variously used in drug delivery systems that increase the efficiency of drugs in vivo.

In this study, by using HPMC as a pharmaceutical formulation, a hydrogel for transdermal drug delivery and a spray-dried solid dispersion for solubilization of poorly soluble drugs for oral use were obtained.

For a novel hydrogel formulation as a transdermal drug delivery system, a hydrogel composed of carrageenan derived from seaweed and locust bean gum which are mainly used in hydrogels as natural polymers, and a hydrogel including HPMC were prepared. SEM analysis was performed to confirm the morphological characteristics and the drug release characteristics were compared. The hydrogel containing 60-70% HPMC based on the solid content of 5% increased adhesive strength compared to the hydrogel not containing HPMC and exhibited improved viscoelasticity of the gel. In addition, it exhibited an ESR of about 20 g per unit g, indicating the potential as a carrier capable of controlling the release of a drug with a highly hygroscopic hydrogel. The cumulative release amount for 30 minutes of niacinamide of a hydrogel composition containing HPMC was 0.13 mg/cm³ for the hydrogels containing 70% HPMC (Hydrogel 4, Hydrogel 9) and 0.28 mg/cm³ for the hydrogels containing 60% (Hydrogel 7). As the content of HPMC in the composition in mg/cm³ decreased, the cumulative release amount increased. As for the HPMC of the hydrogel, the lower the content, the greater the release amount and the higher the content of Gum Extract (GH), and the difference according to the content of Algae Extract (AE) did not show a tendency.

The purpose of spray dried solid dispersion study was to investigate the selectivity of polymers and the suitability of spray drying to enhance nifedipine solubility. Nifedipine alone or in combination with polymers was dissolved in a mixed solvent of methylene chloride and ethanol. The hydrophilic polymers used were PVP K-30, HPMC, HPMCP, Eudragit, and HPMCAS. Each solid dispersion was prepared using a laboratory spray dryer. The spray-dried solid dispersants were characterized by SEM, DSC, and XRPD analysis, and dissolution tests compared the dissolution rates of nifedipine solid dispersants and nifedipine. The results showed that all spray-dried solid dispersions were in an amorphous form. Dissolution tests were performed at pH 1.2 (artificial gastric juice) and pH 6.8 (artificial intestinal juice) to evaluate solid dispersion solubility. The solid dispersion containing HPMC showed a notably enhanced dissolution rate under both pH conditions. Interestingly, HPMCP and HPMCAS showed almost no enhancement of dissolution behavior at pH 1.2, but a significant increase (10 times or higher) over that of the pure polymer at pH 6.8. Solubility enhancement of poorly soluble drugs differs markedly among the polymers used for spray drying. From the results, HPMCP and HPMCAS are suitable as carriers for drugs with poor solubility that require acid resistance.

A drug delivery system formulation for dermal and oral study using excipients with stable bioavailability, including HPMC, and a study on the solubilization and transdermal delivery efficiency of poorly soluble drugs were conducted. Additional application studies through follow-up development that can design and control the release characteristics of various biomedicals and cosmeceutical products by applying this formulation are needed.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

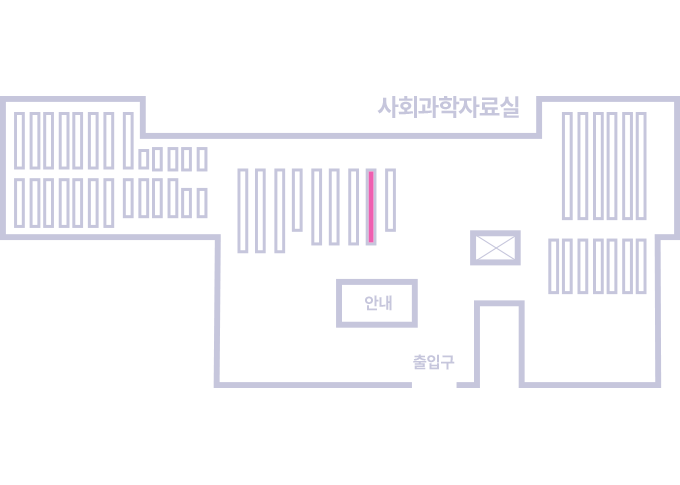

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.