권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

Ⅰ. 서론 9

1.1. 연구 배경 9

1.2. 연구 목적 11

1.3. 이론적 배경 12

1.3.1. 트랙터 변속기 12

1.3.2. 기어 강도 설계 13

1.3.3. 기어 손상 유형 16

1.3.4. 기어 강도 해석 19

Ⅱ. 재료 및 방법 26

2.1. 공시 트랙터 26

2.2. 포장시험 29

2.3. 기어 손상 분석 31

2.3.1. 부변속 A단 31

2.3.2. 부변속 B단 32

2.4. 기어 재질 변경 34

2.5. 시뮬레이션 해석 34

2.5.1. 시뮬레이션 모델링 34

2.5.2. 시뮬레이션 해석 조건 37

2.6. 차축 부하 다이나모 시험 38

2.6.1. 가속 수명 시험 38

2.6.2. 차축 다이나모 시험 장치 구성 40

2.6.3. 차축 다이나모 시험 조건 42

Ⅲ. 결과 및 고찰 45

3.1. 시뮬레이션 모델 개발 및 검증 45

3.2. 재질 변경에 따른 시뮬레이션 해석 결과 48

3.2.1. 부변속 A단 48

3.2.2. 부변속 B단 51

3.3. 차축 다이나모 시험 결과 55

3.3.1. 부변속 A단 55

3.3.2. 부변속 B단 56

3.4. 기어 수명 해석 결과 비교 57

Ⅳ. 결론 및 요약 59

LIST OF REFERENCES 61

ABSTRACT 66

Figure 1. Power flow of tractor for agricultural transmission 12

Figure 2. Gear wear 16

Figure 3. Gear plastic flow 17

Figure 4. Gear pitting 18

Figure 5. Gear breakage 19

Figure 6. A photo of 86 kW class agricultural tractor for field test used in this study 26

Figure 7. 3D model of agricultural tractor transmission used in this study 28

Figure 8. Power flow of agricultural tractor transmission used in this study 28

Figure 9. C type method for agricultural field operation used in this study 30

Figure 10. Results of field test for range shift A gear of 86 kW class agricultural tractor 31

Figure 11. View of gear plastic flow by stages 32

Figure 12. Results of field test for range shift B gear of 86 kW class agricultural tractor 33

Figure 13. Determination of normal chordal dimensions of tooth root critical section for ISO 6336 : Method B (external gears) 33

Figure 14. KISSsoft interface used in this study 35

Figure 15. Inverse power model 39

Figure 16. Configuration of the axle dynamometer system used in this study 41

Figure 17. A photo of the axle dynamometer test of 86 kW class agricultural tractor used in this study 42

Figure 18. Engine performance diagram of 86 kW class agricultural tractor 43

Figure 19. Simulation model of transmission for 86 kW class agricultural tractor transmission used in this study 45

Figure 20. Results of bending safety factor for transmission of 86 kW class agricultural tractor transmission 46

Figure 21. Results of contact safety factor for transmission of 86 kW class agricultural tractor transmission 47

Figure 22. Results of safety factor for range shift A driving gear of 86 kW class agricultural tractor transmission 48

Figure 23. Results of safety factor for range shift A driven gear of 86 kW class agricultural tractor transmission 50

Figure 24. Results of safety factor for range shift B driving gear of 86 kW class agricultural tractor transmission 52

Figure 25. Results of safety factor for range shift B driven gear of 86 kW class agricultural tractor transmission 54

Figure 26. Results of dynamometer test for range shift A gear of 86 kW class agricultural tractor transmission 56

Figure 27. Results of dynamometer test for range shift B gear of 86 kW class agricultural tractor transmission 57

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

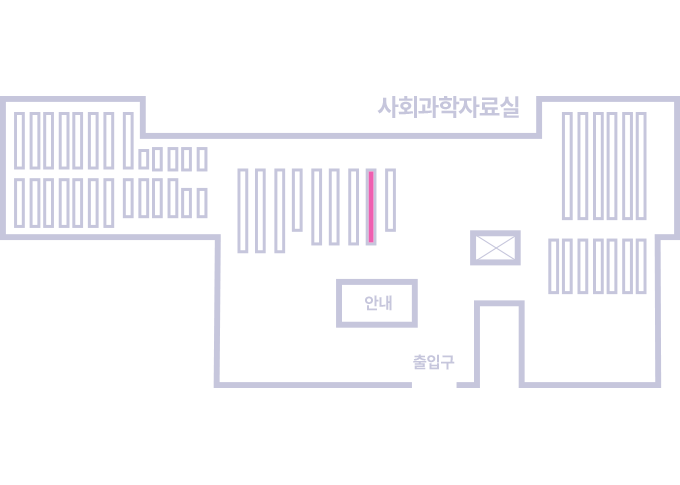

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.