권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

1. 서론 8

1.1. 연구 배경 및 목적 8

1.2. 문헌 조사 11

1.3. 연구 방법 및 내용 14

2. 타이어와 단품 특성 시험 18

2.1. 타이어의 구조 및 기능 18

2.2. Flat Trac 시험기와 시험 방법 21

2.3. Cornering Stiffness(Cα)[이미지참조] 23

2.4. Lateral Stiffness(KL)[이미지참조] 25

2.5. Relaxation Length(RL) 26

3. Relaxation Length 연구를 위한 타이어 단품 시험 31

3.1. Cornering Stiffness(Cα) 단품 시험 결과[이미지참조] 32

3.2. Lateral Stiffness(KL) 단품 시험 결과[이미지참조] 32

3.3. Flat Trac(FTC) 평가를 통한 Relaxation Length 단품 시험 결과 33

4. Relaxation Length 연구를 위한 유한요소해석 35

4.1. 타이어 모델링 35

4.2. 유한요소해석 결과 36

4.2.1. Cornering Stiffness(Cα) 유한요소해석 결과[이미지참조] 36

4.2.2. Lateral Stiffness(KL) 유한요소해석 결과[이미지참조] 37

4.3. 타이어 Part 강성 Variation 38

4.3.1. Tread Part 강성 Variation 39

4.3.2. Sidewall Part 강성 Variation 41

5. 결과 분석 및 고찰 44

5.1. 유한요소해석 결과와 단품 시험 결과 상관성 분석 44

5.2. Relaxation Length 결과 비교 및 상관성 분석 46

5.3. 타이어 Part 강성에 따른 Relaxation Length 영향도 분석 51

5.3.1. Tread Part 강성 Variation에 따른 Relaxation Length 영향도 51

5.3.2. Sidewall Part 강성 Variation에 따른 Relaxation Length 영향도 59

6. 결론 및 향후 연구 계획 68

6.1. 결론 68

6.2. 향후 연구 계획 70

7. 참고 문헌 72

ABSTRACT 73

Fig. 1-1. FTC target in engineering requirement 16

Fig. 1-2. Stiffness map 16

Fig. 1-3. Research method 17

Fig. 2-1. Tire structure diagram 18

Fig. 2-2. Belt cord structure 19

Fig. 2-3. Reinforcement belt structure 21

Fig. 2-4. Flat Trac machine and standard sweep(SL0) test 22

Fig. 2-5. Slip angle input of standard sweep(SL0) test 22

Fig. 2-6. Slip angle input of FTC test 23

Fig. 2-7. Tire slip angle(α) and cornering stiffness by load 24

Fig. 2-8. Lateral stiffness KL test[이미지참조] 25

Fig. 2-9. Lateral stiffness test data 26

Fig. 2-10. Relaxation length 27

Fig. 2-11. Relaxation length model 30

Fig. 4-1. Tire layout and mesh by SLM 35

Fig. 4-2. Cornering stiffness result by ISLM 37

Fig. 4-3. Lateral stiffness simulation 38

Fig. 4-4. Tread part stiffness map 41

Fig. 4-5. Sidewall part stiffness map 43

Fig. 5-1. Cornering stiffness correlation of test and FE simulation 45

Fig. 5-2. Lateral stiffness correlation of test and FE simulation 46

Fig. 5-3. Relaxation length correlation of theoretical equation and Flat... 48

Fig. 5-4. Relaxation length correlation of without correlation equation... 50

Fig. 5-5. Relaxation length correlation of correlation equation... 50

Fig. 6-1. Relaxation length influence by tread part stiffness variation 65

Fig. 6-2. Relaxation length influence by sidewall part stiffness variation 65

This study is about Relaxation length prediction through finite element analysis. Relaxation length is a factor important for handling performance, among the Functional tire characteristics required by Car makers.

To analyze the correlation, Cornering stiffness, Lateral stiffness, Relaxation length obtained from the actual tire tests were compared and analyzed with the values obtained through finite element analysis.

It was found that the absolute values of Cornering stiffness and Lateral stiffness through actual tire test and finite element analysis were different but highly correlated. Also, The theoretical calculated Relaxation length and the Relaxation length through Flat Trac FTC test were highly correlated.

It was confirmed that the calculation of the Relaxation length by converting Lateral stiffness and Cornering stiffness obtained through finite element analysis using the correlation equation obtained, can be predicted by improving accuracy.

Based on the above correlation, FE model was created by variation of design factors that change stiffness of Tread part and Sidewall part, and the influence of Relaxation length were analyzed through finite element analysis. Finally, Relaxation length effects of 14 design factors affecting the Tread part and 7 design factors affecting Sidewall part could be quantified.

If the study data is more stacked and refined, it is not necessary to actually manufacture the tires and conduct a single-product test to meet the Relaxation length target required by the Car maker. After Referring the effects of Relaxation length on design factors and creating FE model considering Trade-Off performance of tire, If Relaxation length calculated by finite element analysis, an optimized structure design can be made to reach the target value quickly.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

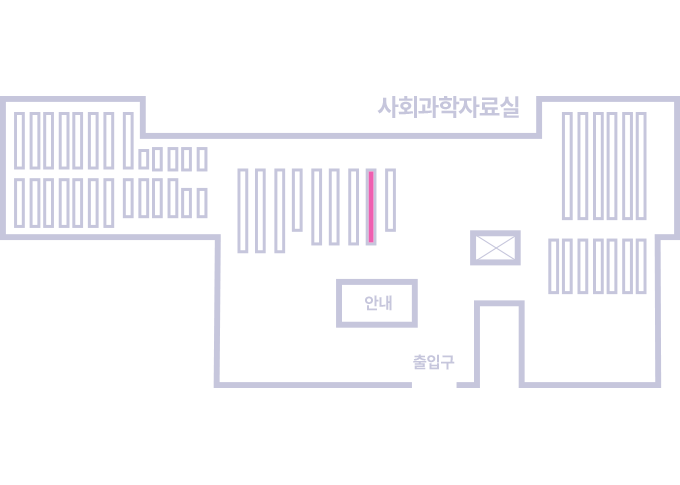

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.