권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

요약문 3

Ⅰ. 서론 10

1.1. 연구배경 및 필요성 10

1.2. 연구목적 및 내용전술한 바와 같이 제작차의 배출가스 16

Ⅱ. 연구내용 및 방법 18

2.1. 유로-6 경유차의 기술 특성 18

2.2. 유럽의 RDE-LDV 규제 22

2.2.1. 일반 요건 (General Requirements) 22

2.2.2. 경계 요건 (Boundary Conditions) 23

2.2.3. 주행경로 요건 (Trip Requirements) 26

2.3. 실제도로 주행 배출가스 평가 방법 30

2.3.1. 이동평균구간 (Moving Averaging Window, MAW) 방법 30

2.3.2. Power Binning 방법 39

2.4. 시험차량 제원 50

2.5. 이동식 배출가스 시험장치 (PEMS) 50

2.6. 차량 동력시스템 모델링 기법 분석 54

2.7. 차량 동력시스템 시뮬레이션 process 61

Ⅲ. 시험 결과 및 고찰 64

3.1. 차대동력계 시험결과 64

3.2. 국내 RDE 주행경로 개발 65

3.2.1. 경로 1 (Route 1) 65

3.2.2. 경로 2 (Route 2) 66

3.2.3. 개발 경로의 특성 분석 및 정상운행의 적합성 68

3.3. 실제도로 주행 배출가스 분석 결과 73

3.3.1. 경로평균 (Distance specific mass emissions) 분석 결과 73

3.3.2. 이동평균구간(MAW) 분석 결과 74

3.3.3. Power binning 분석 결과 81

3.3.4. 실제도로 주행 배출가스 평가 방법들의 비교 85

3.3.5. 에어컨 작동 상태에 따른 이동평균구간 분석 결과 86

3.4. 동력시스템 모델링을 이용한 실제도로 조건에서 배출가스 CO2 배출량 예측 91

3.4.1. 도로구배 및 주행속도를 반영한 배출가스 및 CO2 배출량 예측 92

3.4.2. 실제도로 조건 주행패턴 (급가속, 급감속 등)에 따른 배출가스 및 CO2 배출량 편차 분석 97

3.4.3. 차종별 주행 모드와 실제도로 조건에서의 배출가스 및 CO2 배출량 상관관계 분석 99

Ⅳ. 결론 104

Ⅴ. 참고문헌 106

Fig. 1-1. Share of NOx by 2012(Korea) and by 2013(Europe) 10

Fig. 1-2. Atmospheric environment, Seoul weather information by year, 2014 11

Fig. 1-3. Real-driving NOx emissions for light-duty vehicles (Europe) 11

Fig. 1-4. Real-driving NOx emissions for Korean light-duty vehicles 12

Fig. 1-5. Parallel hybrid power train modeling 13

Fig. 1-6. Advantage of vehicle powertrain level simulation 14

Fig. 1-7. Structure of project consortium 17

Fig. 2-1. Functional Principle of Urea-SCR 19

Fig. 2-2. Functional Principle of LNT 20

Fig. 2-3. Functional Principle of DPF system 21

Fig. 2-4. Flow chart of evaluating dynamic conditions in RDE 25

Fig. 2-5. Illustration of procedure to smooth the interpolated altitude signals 28

Fig. 2-6. Flow chart of evaluating Positive cumulative elevation gain in RDE 29

Fig. 2-7. Vehicle speed versus time 31

Fig. 2-8. Definition of CO2 mass based averaging windows 32

Fig. 2-9. Vehicle CO2 characteristic curve 34

Fig. 2-10. Vehicle CO2 characteristic curve: urban, rural andmotorway driving definitions 34

Fig. 2-11. Primary and secondary tolerance of vehicle CO2 characteristic curve 35

Fig. 2-12. Averaging window weighting function 37

Fig. 2-13. Schematic picture for converting the normalized standardised power frequency into a vehicle specific power frequency 41

Fig. 2-14. Schematic picture of setting up the vehicle specific Veline from the CO2 test results in the 4 phases of the WLTC 48

Fig. 2-15. Flow chart of evaluating power binning in RDE 49

Fig. 2-16. Schematic of PEMS for real driving emission measurement 51

Fig. 2-17. Photographs of PEMS installation to test vehicles 51

Fig. 2-18. Correlation of emission results between PEMS and CVS equipment 52

Fig. 2-19. Comparison of real-time NOx and CO2 emission rate between PEMS and CV 53

Fig. 2-20. Main components of vehicle dynamic simulation model 54

Fig. 2-21. Vertical forces acting on front and real wheels 55

Fig. 2-22. Fuel map, THC emission map and engine full load characteristic curve data 55

Fig. 2-23. Three-dimensional interpolation method (smallest error square method) 56

Fig. 2-24. Gear shifting strategy 57

Fig. 2-25. Improving prediction accuracy of engine operating condition 57

Fig. 2-26. Performance curve of torque converter 58

Fig. 2-27. Power controller logic based on Fuzzy logic 59

Fig. 2-28. Parallel type hybrid power train model (AVL CRUISE) 60

Fig. 2-29. Calculation process of vehicle dynamic simulation model 61

Fig. 2-30. forces acting on a vehicle 62

Fig. 3-1. Chassis dynamometer test results with NEDC and WLTC driving cycles 64

Fig. 3-2. Route 1 for RDE-LDV 65

Fig. 3-3. Route 2 for RDE-LDV 67

Fig. 3-4. Comparison of altitude between route 1 and Route 2 for RDE-LDV 68

Fig. 3-5. Characteristics of RPA in route 1, NEDC, and WLTC 69

Fig. 3-6. Characteristics of RPA in route 2, NEDC, and WLTC 69

Fig. 3-7. CO2 characteristic curve of route 1 70

Fig. 3-8. CO2 characteristic curve of route 2 70

Fig. 3-9. Characteristics of distance-specific NOx emission in route 1 and route 2 73

Fig. 3-10. Characteristics of NOx emission evaluated by MAW in route 1 and route 2 74

Fig. 3-11. CO2 characteristics curve evaluated by MAW with Veh. 5 75

Fig. 3-12. On-road NOx emission evaluated by MAW with Veh. 5 76

Fig. 3-13. Modal data of vehicle speed, exhaust temperature, and EGR (%) with Veh. 5 77

Fig. 3-14. CO2 characteristics curve evaluated by MAW with Veh. 2 78

Fig. 3-15. On-road NOx emission evaluated by MAW with Veh. 2 79

Fig. 3-16. Modal data of vehicle speed, exhaust temperature, and EGR (%) with Veh. 2 80

Fig. 3-17. Characteristics of NOx emission evaluated by power binning in route 1 and 2 81

Fig. 3-18. Weighted NOx emission evaluated by power binning with Veh. 2 82

Fig. 3-19. Weighted NOx emission evaluated by power binning with Veh. 5 84

Fig. 3-20. Comparison of NOx emission evaluated by distance-specific, MAW, and Power binning method 85

Fig. 3-21. Comparison of NOx emission evaluated by MAW between AC/off and AC/on in route 1 86

Fig. 3-22. Comparison of NOx emission evaluated by MAW between AC/off and AC/on in route 2 87

Fig. 3-23. On-road NOx emission evaluated by MAW with Veh. 3 in route 2 88

Fig. 3-24. Modal data of urban with AC off condition of Veh. 3 in route 2 89

Fig. 3-25. Modal data of urban with AC on condition of Veh. 3 in route 2 89

Fig. 3-26. Real driving routes - city, combined and up-down hill 92

Fig. 3-27. Comparative analysis of tested and simulated CO2 results 93

Fig. 3-28. Validating prediction accuracy of Gasoline D model (CO2 emission rate) 94

Fig. 3-29. Validating Prediction accuracy of engine operating point 95

Fig. 3-30. Predicted fuel efficiency and CO2 emission rate of five vehicle models 96

Fig. 3-31. Correlation analysis between vehicle acceleration and CO2 emission rate (g/km) 98

Fig. 3-32. Power binning method - weighting factor applied 99

Fig. 3-33. Power class normalization result 99

Fig. 3-34. Prodicted CO2 emission rate based on simulation and power binning method 101

Fig. 3-35. Fuel efficiency and CO2 emission prediction result (CVS-75, HWFET driving mode) 103

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

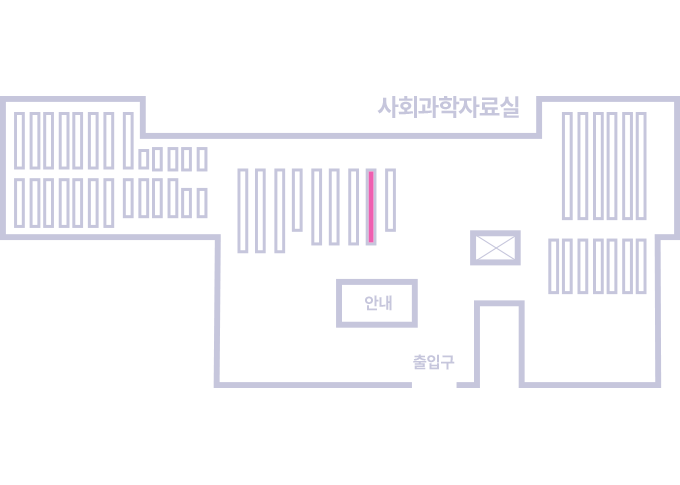

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.