권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

결과 내 검색

동의어 포함

표제지

제출문

최종 연구보고서 초록

요약문

SUMMARY

Contents

목차

제1장 연구개발 과제의 개요 43

제1절 연구개발의 목적 43

제2절 연구개발의 필요성 45

제3절 연구개발의 범위 47

제2장 국내ㆍ외 기술개발 현황 49

제1절 국내 기술개발 현황 49

1. 핵연료 물성 특성 분석 기술 49

2. 핵연료 성능 평가 코드 개발 53

3. 핵연료 조사 시험 기술 54

4. 조사 핵연료의 조사후시험 기술 55

제2절 국외 기술개발 현황 57

1. 핵연료 물성 특성 분석 기술 57

2. 핵연료 성능 평가 개발 63

3. 핵연료 조사시험 기술 67

4. 핵연료 조사후시험 기술 74

제3절 국내ㆍ외 기술 수준 비교 82

제3장 연구개발 수행 내용 및 결과 85

제1절 건식 재가공 산화물 물성 특성 모델 개발 85

1. 건식 산화물 물성 특성 분석 85

가. 건식재가공 핵연료 소결체 제조 85

나. 건식 재가공 핵연료 소결체 특성 87

다. 모의 핵연료 제조 공정 조건 95

2. 열 물성특성 실험 자료 생산 및 특성 모형 개발 97

가. 건식 재가공핵연료의 열팽창 특성 분석 97

나. 건식 재가공핵연료의 열전도 특성 분석 114

다. 열팽창 측정기기의 불확도 평가 128

3. 기계 물성 특성 실험 및 특성 모형 개발 139

가. 탄성계수 139

나. 항복강도 140

다. 크리프 변형 거동 140

라. 건식 재가공핵연료의 탄성계수 측정 141

마. 건식 재가공핵연료의 고온 항복강도 측정 142

바. 건식 재가공핵연료의 파괴 특성 143

사. 건식 재가공핵연료의 크리프 특성 분석 144

4. 연소도에 따른 핵분열기체 확산실험 및 확산모델 152

가. 핵분열기체 확산실험 장치 152

나. 연소도에 따른 핵분열 기체 확산계수 157

제2절 하나로 조사거동 해석 159

1. 물성특성 최적 모델 반영 성능평가 코드 보완 159

가. KAOS 코드의 개요 159

나. KAOS 코드의 기본 구조 160

다. 수치 계산 해법 및 모형 162

라. 핵연료의 열적/기계적 거동 해석 163

2. 하나로 조사시험 이력 및 결과 해석 185

가. 조사시험이력에 따른 건식 재가공핵연료 중심 온도 비교 185

나. 유한요소법 적용에 따른 기계적 성질 비교 192

3. 건식 재가공핵연료 성능 검증 DB 구축 195

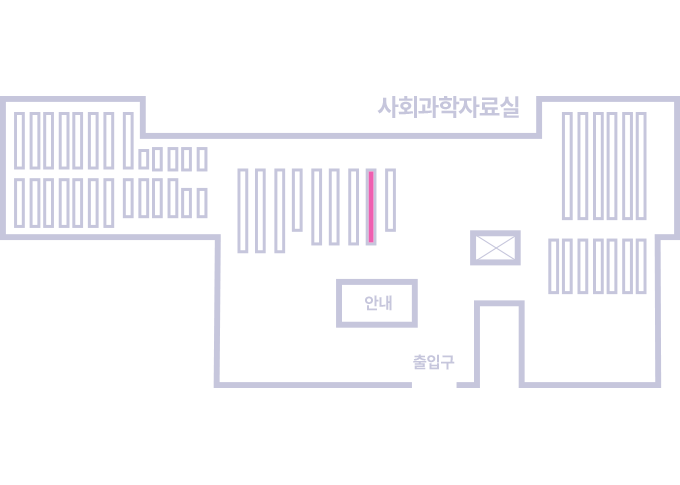

가. 웹기반 건식 재가공핵연료 성능 종합 DB 시스템 설계 및 구축 195

나. 핵연료 성능 검증 DB 설계 199

제3절 건식 재가공핵연료의 계장 조사시험 201

1. 하나로를 이용한 조사시험 및 성능평가 201

가. 6 차 계장 리그 설계 및 제작 201

나. 소결체 드릴링 204

다. 미세용접기술 개발 207

라. 조사시험 기술개발 209

2. 하나로 이용 소결체 계장 조사시험 213

가. 중심온도 부착 연료봉 제조 213

나. 계장 조사시험 리그 조립 215

다. 하나로 조사시험 220

3. 조사후 시험 및 성능평가 229

가. 개요 229

나. 조사후시험 수행방법 229

다. PIE 시험 결과 231

라. 조사후 시험 비교 결과 233

마. 6차 조사후 시험 결과 239

제4장 연구개발 목표 달성도 및 관련 분야에의 기여도 321

제1절 연구개발 목표 달성도 321

제2절 관련 분야에의 기여도 323

제5장 연구개발 결과의 활용 계획 325

제6장 연구개발 과정에서 수집한 해외 과학기술 정보 327

서지정보양식 334

Fig. 2.2.1. Post-irradiation annealing equipment for measuring the diffusion coefficient of fission gas 61

Fig. 3.1.1. Standard fabrication process of simulated fuel 87

Fig. 3.1.2. Apparent density of the UO₂ powder, SS1 and SS2 treated by dynamic milling. 88

Fig. 3.1.3. Apparent density of the UO₂ powder and SS1 treated by turbular milling. 89

Fig. 3.1.4. Green density of the UO₂ powder treated by dynamic milling. 89

Fig. 3.1.5. Green density of the UO₂ powder treated by turbular milling. 90

Fig. 3.1.6. Sintered density of the UO₂ powder treated by dynamic milling. 90

Fig. 3.1.7. Sintered density of the UO₂ powder treated by turbular milling. 91

Fig. 3.1.8. Relative density of UO₂ and SS series by amount of AZB. 92

Fig. 3.1.9. Relative density of UO₂ and M series by amount of AZB. 92

Fig. 3.1.10. Relative density of UO₂ and R series by amount of AZB. 93

Fig. 3.1.11. Microstructure of UO₂. 94

Fig. 3.1.12. Microstructure of SS1. 94

Fig. 3.1.13. Microstructure of SS2. 94

Fig. 3.1.14. Microstructure of SS4. 94

Fig. 3.1.15. Microstructure of R1. 94

Fig. 3.1.16. Microstructure of R2. 94

Fig. 3.1.17. Microstructure of R4. 95

Fig. 3.1.18. Microstructure of M1. 95

Fig. 3.1.19. Microstructure of M2. 95

Fig. 3.1.20. Microstructure of M4. 95

Fig. 3.1.21. Potential energy versus interatomic distance 98

Fig. 3.1.22. Thermal expansion of simulated fuel with solid solution. 103

Fig. 3.1.23. Density variation of simulated fuel with solid solution. 104

Fig. 3.1.24. Termal expansion of simulated fuel with metallic precipitates 105

Fig. 3.1.25. Density variation of simulated fuel with metallic precipitates 106

Fig. 3.1.26. Thermal expansion of reference simulated fuel. 107

Fig. 3.1.27. Density variation of reference simulated fuel. 108

Fig. 3.1.28. Thermal expansion of simulated fuel. 109

Fig. 3.1.29. Density variation of simulated fuel. 109

Fig. 3.1.30. Thermal expansion ratio of simulated fuel with solid solution and UO₂. 111

Fig. 3.1.31. Density ratio of simulated fuel with solid solution and UO₂ 111

Fig. 3.1.32. Thermal expansion ratio of simulated fuel with metallic precipitate and UO₂. 112

Fig. 3.1.33. Density ratio of simulated fuel with metallic precipitate and UO₂. 112

Fig. 3.1.34. Thermal expansion ratio of reference simulated fuel and UO₂ 113

Fig. 3.1.35. Density ratio of reference simulated fuel and UO₂. 113

Fig. 3.1.36. Thermal conductivity of simulated fuel with solid solution. 122

Fig. 3.1.37. Thermal resistivity of simulated fuel with solid solution. 122

Fig. 3.1.38. Thermal conductivity of simulated fuel with metallic ppt 123

Fig. 3.1.39. Thermal resistivity of simulated fuel with metallic ppt. 123

Fig. 3.1.40. Thermal conductivity of reference simulated fuel. 124

Fig. 3.1.41. Thermal resistivity of simulated fuel with metallic ppt. 124

Fig. 3.1.42. Thermal conductivity ratio of simulated fuel with solid solution and UO₂. 126

Fig. 3.1.43. Thermal conductivity ratio of simulated fuel with metallic ppt and UO₂ 126

Fig. 3.1.44. Thermal conductivity ratio of reference simulated fuel and UO₂. 127

Fig. 3.1.45. Thermal conductivity ratio of simulated fuels and UO₂. 127

Fig. 3.1.46. On-set points of standard materials. 131

Fig. 3.1.47. Results of temperature calibration. 132

Fig. 3.1.48. System calibration results of thermal expansion with CRM. 133

Fig. 3.1.49. Thermal expansion and uncertainty of UO₂ fuel. 137

Fig. 3.1.50. Strengh-strain curve for iron illustrating yield strength. 140

Fig. 3.1.51. Strength-strain curve for a ductile and ceramic material illustrating yield strength. 140

Fig. 3.1.52. Schematic illustration of creep curve showing time-dependent plastic strain 141

Fig. 3.1.53. Effect of temperature and stress on the creep curve 142

Fig. 3.1.54. Young' modulus of simulated fuel with burnup. 142

Fig. 3.1.55. Yield strength of simulated fuel with temperature. 143

Fig. 3.1.56. Reference simulated fuel 144

Fig. 3.1.57. High burnup reference simulated fuel 144

Fig. 3.1.58. Reference simulated fuel 144

Fig. 3.1.59. High turnup reference simulated fuel 144

Fig. 3.1.60. Creep strain of reference simulated fuel with time. 146

Fig. 3.1.61. Steady state creep rate of reference simulated fuel with inverse temperature. 146

Fig. 3.1.62. Creep strain with applied stress. 147

Fig. 3.1.63. Steady state creep rate of R1 with applied stress at 1773 K 148

Fig. 3.1.64. Steady state creep rate of R2 with applied stress at 1773 K and 1973 K. 149

Fig. 3.1.65. Creep strain of S-series at 1773 K and 17.5 MPa with amount of solid solution. 150

Fig. 3.1.66. Steady state creep rate of simulated fuel and UO₂ at 1773 K and 17.5. MPa with dopant content 150

Fig. 3.1.67. Creep strain of M-series at 1773 K and 17.5 MPa with time. 151

Fig. 3.1.68. Specimen for diffusion coefficient measurement 152

Fig. 3.1.69. Measurement apparatus for diffusion coefficient 153

Fig. 3.1.70. Fractional release of Xe gas for the simulated fuel (60 GWd/tU) 155

Fig. 3.1.71. ORIGEN-ARP input for the estimation of the irradiation burnup 157

Fig. 3.1.72. Apparent diffusion coefficient of simulated fuel and UO₂ 158

Fig. 3.2.1. Basic calculation flow of KAOS code 161

Fig. 3.2.2. Calculation relation chart of the KAOS code 163

Fig. 3.2.3. A typical temperature distribution in the radial direction 164

Fig. 3.2.4. Region for temperature calculation 168

Fig. 3.2.5. Stress and strain curve for MSS method. 173

Fig. 3.2.6. Finite elements for the pellet and the cladding 179

Fig. 3.2.7. Matrix for the combined finite elements 180

Fig. 3.2.8. External force for the pellet and the cladding 181

Fig. 3.2.9. Linear power rate for the 2nd irradiation test 186

Fig. 3.2.10. Centerline temperature of the 2nd irradiation test 186

Fig. 3.2.11. Linear power rate for the 3rd irradiation test 187

Fig. 3.2.12. Centerline temperature of the 3rd irradiation test 187

Fig. 3.2.13. Linear power rate for the 3rd+4th irradiation test 188

Fig. 3.2.14. Centerline temperature of the 3rd+4th irradiation test 188

Fig. 3.2.15. Linear power rate for the 4th irradiation test 189

Fig. 3.2.16. Centerline temperature of the 4th irradiation test 189

Fig. 3.2.17. Linear power rate for the 5th irradiation test 190

Fig. 3.2.18. Centerline temperature of the 5th irradiation test 190

Fig. 3.2.19. Linear power rate for the 6th irradiation test 191

Fig. 3.2.20. Centerline temperature of the 6th irradiation test 191

Fig. 3.2.21. Clad axial stress for the 6th irradiation test 193

Fig. 3.2.22. Clad hoop stress for the 6th irradiation test 193

Fig. 3.2.23. Gap size variation for the 6th irradiation test 194

Fig. 3.2.24. Rod internal pressure for the 6th irradiation test 194

Fig. 3.2.25. DUPIC fuel database (http://147.43.74.247) 195

Fig. 3.2.26. Database structure and contents 196

Fig. 3.2.27. Nuclear fuel performance evaluation system 198

Fig. 3.3.1. Design of the instrumentation rig 203

Fig. 3.3.2. Loading Test of 6th rig 204

Fig. 3.3.3. The assembled 6th rig 204

Fig. 3.3.4. Mini-element pellet Spec. 205

Fig. 3.3.5. Remote drilling of pellet at hotcell 206

Fig. 3.3.6. Drilled pellet 206

Fig. 3.3.7. Pellets for 6th irradiation test 207

Fig. 3.3.8. Sealing method by Swagelock 207

Fig. 3.3.9. The drawing of seal tube 208

Fig. 3.3.10. The sealing of laser welding method 208

Fig. 3.3.11. The drawing of laser welding 208

Fig. 3.3.12. Laser welded sealing part 209

Fig. 3.3.13. Remote instrumented rig device for irradiation test that accommodates duel mini-element assembly 210

Fig. 3.3.14. The structure of LVDT 211

Fig. 3.3.15. The drawing of LVDT 212

Fig. 3.3.16. The LVDT for fission gas measurement 213

Fig. 3.3.17. The welding of endcap and thermocouple 214

Fig. 3.3.18. Before mini-element welding 215

Fig. 3.3.19. After mini-element welding 215

Fig. 3.3.20. Mini-element assembly 216

Fig. 3.3.21. The process of element assembly 217

Fig. 3.3.22. The completed assembly of instrumented irradiation test rig 218

Fig. 3.3.23. SMS remote monitoring program 222

Fig. 3.3.24. Data acquisition system of instrumented rig 222

Fig. 3.3.25. The list of SMS 223

Fig. 3.3.26. The irradiation hole of HANARO reactor 224

Fig. 3.3.27. Profile of centerline temperature acquired during 6th irradiation test 225

Fig. 3.3.28. Comparison of 5th and 6th of centerline temperature 226

Fig. 3.3.29. Comparison of LHR vs. centerline temperature 227

Fig. 3.3.30. Centerline temperature vs. linear heat rate of Rod1 227

Fig. 3.3.31. Estimation of fission gas release by Vitanza model 228

Fig. 3.3.32. Concentration profile of precipitates of 2nd irradiation dry-process fuel. 252

Fig. 3.3.33. EPMA line scanning with UO₂ for 2nd irradiation fuel. 252

Fig. 3.3.34. EPMA line scanning without UO₂ for 2nd irradiation fuel. 253

Fig. 3.3.35. Precipitate of 2nd irradiation fuel close to void(3.5㎛) 253

Fig. 3.3.36. Precipitate of 2nd irradiation fuel at columnar grain boundary(2㎛) 253

Fig. 3.3.37. Precipitate of 2nd irradiation fuel at large equiaxed grain boundary (1㎛) 254

Fig. 3.3.38. Precipitate of 2nd irradiation fuel at the surface of fuel (0.5㎛) 254

Fig. 3.3.39. Concentration profile of precipitates according to the position of fuel (D42:ppt. on columnar grain. D32:on large equtaxed grain, D22:equiaxed grain, D112:ppt. on surface of the fuel). 254

Fig. 3.3.40. Concentration profile of Mo along the radius of fuel. 255

Fig. 3.3.41. Cut-section view of 2nd irradiation dry-process fuel. 255

Fig. 3.3.42. Overview of microstructure of 2nd irradiation fuel. 256

Fig. 3.3.43. Calculated center-line temperature of dry-process fuel. 256

Fig. 3.3.44. Calculated grain size at center of dry-process fuel. 257

Fig. 3.3.45. Microstructure of polished surface of 2nd irradiation dry-process fuel near the void. 257

Fig. 3.3.46. Microstructure of fractured surface of 2nd irradiation dry-process fuel near the void. 257

Fig. 3.3.47. Metallograph image position map. 258

Fig. 3.3.48. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-0 258

Fig. 3.3.49. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-1. 258

Fig. 3.3.50. Metallogyaph image of 2nd irradiation dry-process fuel at DP-400X-2. 258

Fig. 3.3.51. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-3. 258

Fig. 3.3.52. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-4. 259

Fig. 3.3.53. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-5. 259

Fig. 3.3.54. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-6. 259

Fig. 3.3.55. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-7. 259

Fig. 3.3.56. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-8. 260

Fig. 3.3.57. Metallograph image of 2nd irradiation dry-process fuel at DP-400X-9. 260

Fig. 3.3.58. SEM image position map. 260

Fig. 3.3.59. SEM image of 2nd irradiation dry-process fuel at 6-1. 260

Fig. 3.3.60. SEM image of 2nd irradiation dry-process fuel at 6-2. 260

Fig. 3.3.61. SEM image of 2nd irradiation dry-process fuel at 6-3. 261

Fig. 3.3.62. SEM image of 2nd irradiation dry-process fuel at 6-4. 261

Fig. 3.3.63. SEM image of 2nd irradiation dry-process fuel at 6-4(2). 261

Fig. 3.3.64. SEM image of 2nd irradiation dry-process fuel at 6-5. 261

Fig. 3.3.65. SEM image of 2nd irradiation dry-process fuel at 6-5. 261

Fig. 3.3.66. SEM image of 2nd irradiation dry-process fuel at 6-6. 261

Fig. 3.3.67. SEM image of 2nd irradiation dry-process fuel at 6-7. 262

Fig. 3.3.68. SEM image of 2nd irradiation dry-process fuel at 6-7(2). 262

Fig. 3.3.69. SEM image of 2nd irradiation dry-process fuel at 6-8. 262

Fig. 3.3.70. SEM image of 2nd irradiation dry-process fuel at 6-9. 262

Fig. 3.3.71. SEM image of 2nd irradiation dry-process fuel at 6-9. 262

Fig. 3.3.72. SEM image of 2nd irradiation dry-process fuel at 6-10. 262

Fig. 3.3.73. SEM image of 2nd irradiation dry-process fuel at 6-11. 263

Fig. 3.3.74. SEM image of 2nd irradiation dry-process fuel at 6-12. 263

Fig. 3.3.75. SEM image of 2nd irradiation dry-process fuel at 3-13. 263

Fig. 3.3.76. SEM image of 2nd irradiation dry-process fuel at 3-13. 263

Fig. 3.3.77. SEM image of 2nd irradiation dry-process fuel at 3-14. 263

Fig. 3.3.78. SEM image of 2nd irradiation dry-process fuel at 3-14(2). 263

Fig. 3.3.79. SEM image of 2nd irradiation dry-process fuel at 1-16. 264

Fig. 3.3.80. SEM image of 2nd irradiation dry-process fuel at 1-17. 264

Fig. 3.3.81. SEM image of 2nd irradiation dry-process fuel at 6-18. 264

Fig. 3.3.82. SEM image of 2nd irradiation dry-process fuel at 6-18. 264

Fig. 3.3.83. SEM image of 2nd irradiation dry-process fuel at 6-19. 264

Fig. 3.3.84. Concentration profile of fission products of 3rd irradiation pellet. 265

Fig. 3.3.85. Concentration profile of fission products of 3rd irradiation pellet(2). 265

Fig. 3.3.86. Concentration profile of fission products of 3rd irradiation pellet(3). 266

Fig. 3.3.87. Microstructure of 3rd irradiation pellet. 266

Fig. 3.3.88. Microstructure of 3rd irradiation pellet in position of r/r0=200㎛ (D3-01). 267

Fig. 3.3.89. Microstructure of 3rd irradiation pellet in position of r/r0=400㎛ (D3-02). 267

Fig. 3.3.90. Microstructure of 3rd irradiation pellet in position of r/r0=600㎛ (D3-03). 267

Fig. 3.3.91. Microstructure of 3rd irradiation pellet in position of r/r0=800㎛ (D3-04). 267

Fig. 3.3.92. Microstructure of 3rd irradiation pellet in position of r/r0=1000㎛ (D3-05). 267

Fig. 3.3.93. Microstructure of 3rd irradiation pellet tn position of r/r0=1200㎛ (D3-06). 267

Fig. 3.3.94. Microstructure of 3rd irradiation pellet in position of r/r0=1400㎛ (D3-07). 268

Fig. 3.3.95. Microstructure of 3rd irradiation pellet in position of r/r0=1600㎛ (D3-08). 268

Fig. 3.3.96. Microstructure of 3rd irradiation pellet in position of r/r0=1800㎛ (D3-09). 268

Fig. 3.3.97. Microstructure of 3rd irradiation pellet in position of r/r0=2000㎛ (D3-10). 268

Fig. 3.3.98. Microstructure of 3rd irradiation pellet in position of r/r0=2200㎛ (D3-11). 268

Fig. 3.3.99. Microstructure of 3rd irradiation pellet in position of r/r0=2400㎛ (D3-12). 268

Fig. 3.3.100. Microstructure of 3rd irradiation pellet in position of r/r0=2600㎛ (D3-13). 269

Fig. 3.3.101. Microstructure of 3rd irradiation pellet in position of r/r0=2800㎛ (D3-14). 269

Fig. 3.3.102. Microstructure of 3rd irradiation pellet in position of r/r0=3000㎛ (D3-15). 269

Fig. 3.3.103. Microstructure of 3rd irradiation pellet in position of r/r0=3200㎛ (D3-16). 269

Fig. 3.3.104. Microstructure of 3rd irradiation pellet in position of r/r0=3400㎛ (D3-17). 269

Fig. 3.3.105. Microstructure of 3rd irradiation pellet in position of r/r0=3600㎛ (D3-18). 269

Fig. 3.3.106. Microstructure of 3rd irradiation pellet ill position of r/r0=3800㎛ (D3-19). 270

Fig. 3.3.107. Microstructure of 3rd irradiation pellet in position of r/r0=4000㎛ (D3-20). 270

Fig. 3.3.108. Microstructure of 3rd irradiation pellet in position of r/r0=4200㎛ (D3-21). 270

Fig. 3.3.109. Microstructure of 3rd irradiation pellet in position of r/r0=4400㎛ (D3-22). 270

Fig. 3.3.110. Microstructure of 3rd irradiation pellet in position of r/r0=4600㎛ (D3-23). 270

Fig. 3.3.111. Microstructure of 3rd irradiation pellet in position of r/r0=4800㎛ (D3-24). 270

Fig. 3.3.112. Microstructure of 3rd irradiation pellet in position of r/r0=5000㎛ (D3-25). 271

Fig. 3.3.113. Microstructure of 3rd irradiation pellet in position of r/r0=5000㎛ (D3-26). 271

Fig. 3.3.114. Microstructure of 3rd irradiation pellet in position of r/r0=5000㎛ (D3-27). 271

Fig. 3.3.115. Microstructure of 3rd irradiation pellet in position of r/r0=5100㎛ (D3-28). 271

Fig. 3.3.116. EPMA line scanning of fission products of D4-1 Fuel. 272

Fig. 3.3.117. EPMA line scanning of fission products of D4-1 Fuel (2). 272

Fig. 3.3.118. EPMA line scanning of fission products of D4-1 Fuel (3). 273

Fig. 3.3.119. EPMA line scanning of fission products of D4-1 Fuel (4). 273

Fig. 3.3.120. EPMA line scanning of D4-21 SIMFUEL (OREOX) 274

Fig. 3.3.121. EPMA line scanning of D4-21 SIMFUEL (OREOX) (2). 274

Fig. 3.3.122. Microstructure of dry process fuel of D4-1 (3rd-4th irradiation). 275

Fig. 3.3.123. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=200㎛ (D41A-02). 276

Fig. 3.3.124. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=400㎛ (D41A-03). 276

Fig. 3.3.125. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=600㎛ (D41A-04). 276

Fig. 3.3.126. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=800㎛ (D41A-05). 276

Fig. 3.3.127. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=1000㎛ (D41A-06). 276

Fig. 3.3.128. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=1200㎛ (D41A-07). 276

Fig. 3.3.129. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=1400㎛ (D41A-08). 277

Fig. 3.3.130. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=1600㎛ (D41A-09). 277

Fig. 3.3.131. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=1800㎛ (D41A-10). 277

Fig. 3.3.132. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=2000㎛ (D41A-11). 277

Fig. 3.3.133. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=2200㎛ (D41A-12). 277

Fig. 3.3.134. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=2400㎛ (D41A-13). 277

Fig. 3.3.135. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=2600㎛ (D41A-14). 278

Fig. 3.3.136. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=2800㎛ (D41A-15). 278

Fig. 3.3.137. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=3000㎛ (D41A-16). 278

Fig. 3.3.138. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=3200㎛ (D41A-17). 278

Fig. 3.3.139. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=3400㎛ (D41A-18). 278

Fig. 3.3.140. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=3600㎛ (D41A-19). 278

Fig. 3.3.141. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=3800㎛ (D41A-20). 279

Fig. 3.3.142. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4000㎛ (D41A-21). 279

Fig. 3.3.143. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4200㎛ (D41A-22). 279

Fig. 3.3.144. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4400㎛ (D41A-23). 279

Fig. 3.3.145. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4600㎛ (D41A-24). 279

Fig. 3.3.146. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4800㎛ (D41A-25). 279

Fig. 3.3.147. Microstructure of dry process fuel of 3rd+4th irradiation at r/r0=4900㎛ (D41A-26). 280

Fig. 3.3.148. Microstructure of dry process SIMFUEL of D4-21(4th irradiation, OREOX). 280

Fig. 3.3.149. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=0㎛. 281

Fig. 3.3.150. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=200㎛. 281

Fig. 3.3.151. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=400㎛. 281

Fig. 3.3.152. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=600㎛. 281

Fig. 3.3.153. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=800㎛. 281

Fig. 3.3.154. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=1000㎛. 281

Fig. 3.3.155. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=1200㎛. 282

Fig. 3.3.156. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=1400㎛. 282

Fig. 3.3.157. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=1600㎛. 282

Fig. 3.3.158. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=1800㎛. 282

Fig. 3.3.159. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=2000㎛. 282

Fig. 3.3.160. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=2200㎛. 282

Fig. 3.3.161. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=2400㎛. 283

Fig. 3.3.162. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=2600㎛. 283

Fig. 3.3.163. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=2800㎛. 283

Fig. 3.3.164. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=3000㎛. 283

Fig. 3.3.165. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=3200㎛. 283

Fig. 3.3.166. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=3400㎛. 283

Fig. 3.3.167. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=3600㎛. 284

Fig. 3.3.168. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=3800㎛. 284

Fig. 3.3.169. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4000㎛. 284

Fig. 3.3.170. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4200㎛. 284

Fig. 3.3.171. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4400㎛. 284

Fig. 3.3.172. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4600㎛. 284

Fig. 3.3.173. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4800㎛. 285

Fig. 3.3.174. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=4900㎛. 285

Fig. 3.3.175. Microstructure of dry process fuel of 4th irradiation SIMFUEL at r/r0=5000㎛. 285

Fig. 3.3.176. Microstructure of dry process fuel of D5-3 285

Fig. 3.3.177. Microstructure of dry process fuel of D5-5 285

Fig. 3.3.178. Microstructure of D5I instrumented with thermocouple. 286

Fig. 3.3.179. Schematic detail of thermocouple. 286

Fig. 3.3.180. Thermocouple installed in D5I pellet. 286

Fig. 3.3.181. Magnified view of thermocouple. 286

Fig. 3.3.182. Insulating material of Mg between tantalum sheath and thermoelectric wire. 286

Fig. 3.3.183. Mg between tantalum sheath and thermoelectric wire. 286

Fig. 3.3.184. Microstructure of D5I, r/r0=1.0 (From bull to center with equi-distance 500㎛) 287

Fig. 3.3.185. Microstructure of D5I, r/r0=0.95. 287

Fig. 3.3.186. Microstructure of D5I, r/r0=0.9. 287

Fig. 3.3.187. Microstructure of D5I, r/r0=0.85. 287

Fig. 3.3.188. Microstructure of D5I, r/r0=0.80. 287

Fig. 3.3.189. Microstructure of D5I, r/r0=0.75. 287

Fig. 3.3.190. Microstructure of D5I, r/r0=0.70. 288

Fig. 3.3.191. Microstructure of D5I, r/r0=0.65. 288

Fig. 3.3.192. Microstructure of D5I, r/r0=0.60. 288

Fig. 3.3.193. Microstructure of D5I, r/r0=0.55. 288

Fig. 3.3.194. Microstructure of D5I, r/r0=0.52. 288

Fig. 3.3.195. Microstructure of D5I, r/r0=1.0. 288

Fig. 3.3.196. Microstructure of D5I, r/r0=0.9. 289

Fig. 3.3.197. Microstructure of D5I, r/r0=0.8. 289

Fig. 3.3.198. Microstructure of D5I, r/r0=0.7. 289

Fig. 3.3.199. Microstructure of D5I, r/r0=0.6. 289

Fig. 3.3.200. Microstructure of D5I, r/r0=0.55, near to the thermocouple. 289

Fig. 3.3.201. Microstructure of D5I, r/r0=0.55, near to the thermocouple. 289

Fig. 3.3.202. Microstructure of D5N, r/r0=1.0. 290

Fig. 3.3.203. Microstructure of D5N, r/r0=0.9. 290

Fig. 3.3.204. Microstructure of D5N, r/r0=0.8. 290

Fig. 3.3.205. Microstructure of D5N, r/r0=0.7. 290

Fig. 3.3.206. Microstructure of D5N, r/r0=0.6. 290

Fig. 3.3.207. Microstructure of D5N, r/r0=0.5. 290

Fig. 3.3.208. Microstructure of fractured specimen of D5N, r/r0=0.68 291

Fig. 3.3.209. Microstructure of fractured specimen of D5N, r/r0=0.68(2) 291

Fig. 3.3.210. Microstructure of fractured specimen of D5N, r/r0=0.68(3) 291

Fig. 3.3.211. Microstructure of fractured specimen of D5N, r/r0=0.68(4) 291

Fig. 3.3.212. Microstructure of fractured specimen of D5N, r/r0=0.68(5) 291

Fig. 3.3.213. Microstructure of fractured specimen of D5N, r/r0=0.68(6) 291

Fig. 3.3.214. Microstructure of fractured specimen of D5N, r/r0=0.68(7) 292

Fig. 3.3.215. Microstructure of fractured specimen of D5N, r/r0=0.8 292

Fig. 3.3.216. Microstructure of fractured specimen of D5N, r/r0=0.8(2) 292

Fig. 3.3.217. Microstructure of fractured specimen of D5N, r/r0=0.8(3) 292

Fig. 3.3.218. Microstructure of fractured specimen of D5N, r/r0=1.0 292

Fig. 3.3.219. Specifications of the dry-processed pellets for 6th irradiation. 293

Fig. 3.3.220. Location of the pellets for destructive tests of optical microscope and SEM. 293

Fig. 3.3.221(a). Visual inspection of the irradiation rig of DUPIC-6. 294

Fig. 3.3.221(b). Cutting and disassembly of DUPIC-6 irradiation rig. 294

Fig. 3.3.222. Total counts for DUPIC 6th pellet in the gamma scanning. 295

Fig. 3.3.223. Gamma spectrum of DUPTC 6th pellet (A-6). 295

Fig. 3.3.224. Gamma spectrum of DUPTC 6th pellet (B-6). 296

Fig. 3.3.225. Gamma spectrum of DUPTC 6th pellet (C-6). 296

Fig. 3.3.226. Diameter of the DUPTC 6th pellet (A-6) 297

Fig. 3.3.227. Diameter of the DUPTC 6th pellet (B-6) 297

Fig. 3.3.228. Diameter of the DUPTC 6th pellet (C-6) 298

Fig. 3.3.229. Microstructure of D6-15 at the center of pellet. 298

Fig. 3.3.230. Microstructure of D6-15 at the middle(M) of pellet. 299

Fig. 3.3.231. Microstructure of D6-15 at the middle(M1) of pellet. 299

Fig. 3.3.232. Microstructure of D6-15 at the surface of pellet. 300

Fig. 3.3.233. Microstructure of D6-13 at the center of pellet. 300

Fig. 3.3.234. Microstructure of D6-13 at the middle(M) of pellet. 301

Fig. 3.3.235. Microstructure of D6-13 at the middle(M1) of pellet. 301

Fig. 3.3.236. Microstructure of D6-13 at the surface of pellet. 302

Fig. 3.3.237. Microstructure of specimen D6-15 303

Fig. 3.3.238. Microstructure of center specimen of D6-15 (1) 303

Fig. 3.3.239. Microstructure of center specimen of D6-15 (2) 303

Fig. 3.3.240. Microstructure of center specimen of D6-15 (3) 303

Fig. 3.3.241. Microstructure of center specimen of D6-15 (4) 303

Fig. 3.3.242. Microstructure of center specimen of D6-15 (5) 303

Fig. 3.3.243. Microstructure of center specimen of D6-15 (6) 304

Fig. 3.3.244. Microstructure of center specimen of D6-15 (7) 304

Fig. 3.3.245. Microstructure of center specimen of D6-15 (8) 304

Fig. 3.3.246. Microstructure of center specimen of D6-15 (9) 304

Fig. 3.3.247. Microstructure of center specimen of D6-15 (10) 304

Fig. 3.3.248. Microstructure of center specimen of D6-15 (11) 304

Fig. 3.3.249. Microstructure of center specimen of D6-15 (12) 305

Fig. 3.3.250. Microstructure of center specimen of D6-15 (13) 305

Fig. 3.3.251. Microstructure of center specimen of D6-15 (14) 305

Fig. 3.3.252. Microstructure of center specimen of D6-15 (15) 305

Fig. 3.3.253. Microstructure of center specimen of D6-15 (16) 305

Fig. 3.3.254. Microstructure of center specimen of D6-15 (17) 305

Fig. 3.3.255. Microstructure of center specimen of D6-15 (18) 306

Fig. 3.3.256. Microstructure of center specimen of D6-15 (19) 306

Fig. 3.3.257. Microstructure of center specimen of D6-15 (20) 306

Fig. 3.3.258. Microstructure of center specimen of D6-15 (21) 306

Fig. 3.3.259. Microstructure of center specimen of D6-15 (22) 306

Fig. 3.3.260. Microstructure of middle specimen of D6-15 (1) 307

Fig. 3.3.261. Microstructure of middle specimen of D6-15 (2) 307

Fig. 3.3.262. Microstructure of middle specimen of D6-15 (3) 307

Fig. 3.3.263. Microstructure of middle specimen of D6-15 (4) 307

Fig. 3.3.264. Microstructure of middle specimen of D6-15 (5) 307

Fig. 3.3.265. Microstructure of middle specimen of D6-15 (6) 307

Fig. 3.3.266. Microstructure of middle specimen of D6-15 (7) 308

Fig. 3.3.267. Microstructure of middle specimen of D6-15 (8) 308

Fig. 3.3.268. Microstructure of middle specimen of D6-15 (9) 308

Fig. 3.3.269. Microstructure of middle specimen of D6-15 (10) 308

Fig. 3.3.270. Microstructure of middle specimen of D6-15 (11) 308

Fig. 3.3.271. Microstructure of middle specimen of D6-15 (12) 308

Fig. 3.3.272. Microstructure of middle specimen of D6-15 (13) 309

Fig. 3.3.273. Microstructure of middle specimen of D6-15 (14) 309

Fig. 3.3.274. Microstructure of middle specimen of D6-15 (15) 309

Fig. 3.3.275. Microstructure of middle specimen of D6-15 (16) 309

Fig. 3.3.276. Microstructure of middle specimen of D6-15 (17) 309

Fig. 3.3.277. Microstructure of specimen D6-33(1) 310

Fig. 3.3.278. Microstructure of specimen D6-33(2) 310

Fig. 3.3.279. Microstructure of specimen D6-33(3) 310

Fig. 3.3.280. Microstructure of specimen D6-33(4) 310

Fig. 3.3.281. Microstructure of center specimen of D6-33(1) 310

Fig. 3.3.282. Microstructure of center specimen of D6-33(2) 310

Fig. 3.3.283. Microstructure of center specimen of D6-33(3) 311

Fig. 3.3.284. Microstructure of center specimen of D6-33(4) 311

Fig. 3.3.285. Microstructure of center specimen of D6-33(5) 311

Fig. 3.3.286. Microstructure of center specimen of D6-33(6) 311

Fig. 3.3.287. Microstructure of center specimen of D6-33(7) 311

Fig. 3.3.288. Microstructure of center specimen of D6-33(8) 311

Fig. 3.3.289. Microstructure of center specimen of D6-33(9) 312

Fig. 3.3.290. Microstructure of center specimen of D6-33(10) 312

Fig. 3.3.291. Microstructure of center specimen of D6-33(11) 312

Fig. 3.3.292. Microstructure of center specimen of D6-33(12) 312

Fig. 3.3.293. Microstructure of center specimen of D6-33(13) 312

Fig. 3.3.294. Microstructure of center specimen of D6-33(14) 312

Fig. 3.3.295. Microstructure of center specimen of D6-33(15) 313

Fig. 3.3.296. Microstructure of center specimen of D6-33(16) 313

Fig. 3.3.297. Microstructure of center specimen of D6-33(17) 313

Fig. 3.3.298. Microstructure of center specimen of D6-33(18) 313

Fig. 3.3.299. Microstructure of center specimen of D6-33(19) 313

Fig. 3.3.300. Microstructure of center specimen of D6-33(20) 313

Fig. 3.3.301. Microstructure of center specimen of D6-33(21) 314

Fig. 3.3.302. Microstructure of center specimen of D6-33(22) 314

Fig. 3.3.303. Microstructure of center specimen of D6-33(23) 314

Fig. 3.3.304. Microstructure of center specimen of D6-33(24) 314

Fig. 3.3.305. Microstructure of center specimen of D6-33(25) 314

Fig. 3.3.306. Microstructure of center specimen of D6-33(26) 314

Fig. 3.3.307. Microstructure of center specimen of D6-33(27) 315

Fig. 3.3.308. Microstructure of center specimen of D6-33(28) 315

Fig. 3.3.309. Microstructure of center specimen of D6-33(29) 315

Fig. 3.3.310. Microstructure of center specimen of D6-33(30) 315

Fig. 3.3.311. Microstructure of center specimen of D6-33(31) 315

Fig. 3.3.312. Microstructure of center specimen of D6-33(32) 315

Fig. 3.3.313. Microstructure of center specimen of D6-33(33) 316

Fig. 3.3.314. Microstructure of center specimen of D6-33(34) 316

Fig. 3.3.315. Microstructure of center specimen of D6-33(35) 316

Fig. 3.3.316. Microstructure of middle specimen of D6-33(1) 316

Fig. 3.3.317. Microstructure of middle specimen of D6-33(2) 316

Fig. 3.3.318. Microstructure of middle specimen of D6-33(3) 317

Fig. 3.3.319. Microstructure of middle specimen of D6-33(4) 317

Fig. 3.3.320. Microstructure of middle specimen of D6-33(5) 317

Fig. 3.3.321. Microstructure of middle specimen of D6-33(6) 317

Fig. 3.3.322. Microstructure of surface specimen of D6-33(1) 317

Fig. 3.3.323. Microstructure of surface specimen of D6-33(2) 317

Fig. 3.3.324. Microstructure of surface specimen of D6-33(3) 318

Fig. 3.3.325. Microstructure of surface specimen of D6-33(4) 318

Fig. 3.3.326. Microstructure of surface specimen of D6-33(5) 318

Fig. 3.3.327. Microstructure of surface specimen of D6-33(6) 318

Fig. 3.3.328. Microstructure of surface specimen of D6-33(7) 318

Fig. 3.3.329. Microstructure of surface specimen of D6-33(8) 318

Fig. 3.3.330. Microstructure of surface specimen of D6-33(9) 319

Fig. 3.3.331. Microstructure of surface specimen of D6-33(10) 319

Fig. 3.3.332. Microstructure of surface specimen of D6-33(11) 319

Fig. 3.3.333. Microstructure of surface specimen of D6-33(12) 319

Fig. 3.3.334. Microstructure of surface specimen of D6-33(13) 319

*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.