권호기사보기

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 대표형(전거형, Authority) | 생물정보 | 이형(異形, Variant) | 소속 | 직위 | 직업 | 활동분야 | 주기 | 서지 | |

|---|---|---|---|---|---|---|---|---|---|

| 연구/단체명을 입력해주세요. | |||||||||

|

|

|

|

|

|

* 주제를 선택하시면 검색 상세로 이동합니다.

표제지

목차

1. 서론 11

1.1. 연구 배경 11

1.2. 연구 개발 현황 13

1.3. 연구 목적, 방법 및 범위 14

2. 이론 및 문헌고찰 15

2.1. 현행 수소 제조 방법 16

2.1.1. 수증기 개질법(Steam Reforming) 16

2.1.2. 부분 산화법 (Partial Oxidation) 19

2.1.3. 물의 전기분해 19

2.1.4. 플라즈마 열분해 20

2.1.5. 태양열 aerosol flow 공정 21

2.1.6. 기타 제조 방법 22

2.2. 탄화수소 분해법에 의한 수소의 제조 22

2.2.1. 천연가스(메탄)의 직접 열분해법 23

2.2.2. 탄화수소의 촉매 분해법 25

2.2.3. 수중기 개질법과의 비교 26

2.3. 탄소 촉매 28

2.3.1. Carbon Black 29

2.4. 유동층 반응기의 이용 35

2.4.1. 유동층의 수력학적 특성 37

2.4.2. 흐름 영역 37

2.4.3. Pressure Drop - versus - Velocity Diagram 41

2.4.4. 최소 유동화 속도, Umf(이미지참조) 42

2.4.5. 입자의 Geldart 분류 45

3. 실험 48

3.1. 최소 유동화 속도의 결정 48

3.2. 반응실험 장치 및 방법 51

4. 실험결과 및 검토 54

4.1. 반응 온도의 영향 60

4.2. 반응 가스 유속의 영향 64

4.3. 카본블랙 촉매의 비표면적에 따른 영향 69

4.4. 카본블랙 촉매량 변화에 따른 영향 74

4.5. 활성화 에너지 77

4.6. 장시간 반응(long-term test) 및 촉매의 재사용에 따른 활성 변화 81

4.7. 생성된 카본의 침적량에 따른 영향 87

4.8. 반응 후 카본블랙의 물리 화학적 특성 및 표면 분석 91

5. 결론 100

References 101

Nomenclature 105

Appendix 107

Appendix A : TCD 검량곡선 107

Appendix B : 활성화 에너지 108

Abstract 111

Figure 1. Applications of Hydrogen. 18

Figure 2. Gibbs free energy of formation for various hydrocarbons as a... 24

Figure 3. Temperature Dependence of Hydrogen Concentration... 27

Figure 4. Application of carbon black. 31

Figure 5. Various forms of contacting of a batch of solids by fluid. 39

Figure 6. Pressure drop-versus-velocity. 43

Figure 7. Geldart classification of particles for air at ambient conditions. 47

Figure 8. Pressure Drop Measurement. 50

Figure 9. Schematic of fluidized bed reactor system. 53

Figure 10. Minimum fluidization velocity of carbon black(N330). 55

Figure 11. Minimum fluidization velocity of carbon black(HI-900L). 56

Figure 12. Minimum fluidization velocity of carbon black(HI-20L). 57

Figure 13. Minimum fluidization velocity of carbon black(HI-170). 58

Figure 14. Minimum fluidization velocity of carbon black 59

Figure 15. CH₄ conversion vs. time over CB(HI-170)... 61

Figure 16. CH₄ decomposition rate vs. time over CB(HI-170)... 62

Figure 17. CH₄ conversion vs. time over carbon blacks... 63

Figure 18. CH₄ conversion vs. time over CB(N330)... 65

Figure 19. CH₄ decomposition rate vs. time over CB(N330)... 66

Figure 20. CH₄ conversion vs. time over carbon blacks... 67

Figure 21. CH₄ decomposition rate vs. time over carbon blacks... 68

Figure 22. CH₄ conversion vs. time over carbon blacks... 70

Figure 23. CH₄ conversion vs. surface area over carbon blacks... 71

Figure 24. CH₄ decomposition rate VS. time over carbon blacks... 72

Figure 25. CH₄ decomposition vs. surface area over carbon blacks 73

Figure 26. CH₄ conversion vs. time over CB(N330)... 75

Figure 27. CH₄ conversion vs. time over CB(N330)... 76

Figure 28. Arrhenius plot for methane decomposition... 79

Figure 29. Arrhenius plot for methane decomposition... 80

Figure 30. CH₄ conversion vs. time over CB(N330) 83

Figure 31. Minimum fluidization velocity of used carbon black(N330). 84

Figure 32. CH₄ conversion vs. time over CB(N330)... 85

Figure 33. CH₄ decomposition rate vs. time over CB(N330)... 86

Figure 34. CH₄ conversion and carbon deposit vs. time over CB(N330) 89

Figure 35. The specific carbon deposition(Wc) at activity stabilization vs....(이미지참조) 90

Figure 36. TEM images for carbon black(N330). 96

Figure 37. TEM images for carbon black(HI-900L). 97

Figure 38. TEM images for carbon blacks. 98

Figure 39. TEM images for carbon black(Ketjen black EC 600JD) 99

Figure A-1. CH₄ conversion (%) vs. relative H₂ area 107

Hydrogen is regarded as the ultimate clean power source of the future. However, conventional processes of hydrogen production, such as the steam reforming and partial oxidation of hydrocarbons, accompany simultaneous production of CO₂. On the contrary, decomposition of methane produces no CO₂. This method can avoid bothersome coking and subsequent catalyst regeneration that are required when using transition metal catalysts or a very high temperature for noncatalytic thermal decomposition. Another advantage is that the clean carbon produced can be utilized as a valuable byproduct.

As the reaction proceeds the produced carbon deposited on the surfaces of carbons catalysts and the particle size of carbons catalysts get bigger and bigger. When a fixed bed reactor is used, the reactor will be completely filled with produced carbons and the flow path for reactant gas is blocked in the long run.

In order to solve avoid these problems, a fluidized bed reactor was proposed in this study. A fluidized bed system does provide constant flow of solids through the reaction zone, which makes it particularly suitable for the continuous addition and withdrawal of carbon particles from the reactor.

In this study, several kinds of carbons blacks were employed as the catalyst in a fluidized bed reactor to examine the methane decomposition activity. A batch type fluidized bed reactor system was tested and effects of the parameters on the reaction rate were investigated. The morphology of carbon deposited on the carbon blacks was investigated by SEM and TEM.

The initial activity of carbon black catalyst decreased but it quickly reached quasi-steady state and maintained for longer than 8 hrs regardless of reaction temperature. The higher gas velocity resulted in a lower methane conversion because the retention time of methane in the fluidized bed decreased as the flow rate of reactant gas was increased. The higher surface area of catalyst resulted in a higher methane conversion. The activity of used carbon black for methane decomposition quickly reached a quasi-steady state.

The SEM and TEM images showed that the fresh carbon black particles were largely rounded and the surfaces look smooth. The deposited carbon formed many protrusions on the surfaces, in cone-shape or pillars, and the particles looked alike sea squirts. As the carbon deposition went on, the particles become larger and more particles become stuck together. It is believed that since the carbon morphology changes continuously due to the carbon deposition, an active site may disappear on the one hand due to merging of protrusions or agglomeration of particles but on the other hand another site may be generated at the edge or defect of growing graphite layer in the carbon black. One plausible explanation for this may be that overall number of the active sites remains almost constant during the reaction.*표시는 필수 입력사항입니다.

| 전화번호 |

|---|

| 기사명 | 저자명 | 페이지 | 원문 | 기사목차 |

|---|

| 번호 | 발행일자 | 권호명 | 제본정보 | 자료실 | 원문 | 신청 페이지 |

|---|

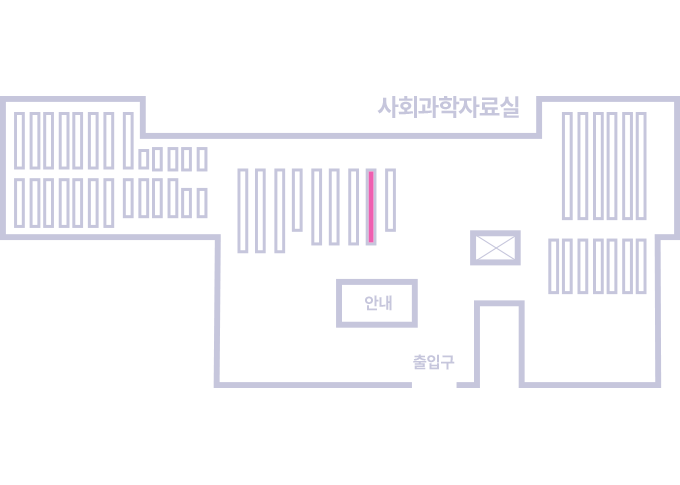

도서위치안내: / 서가번호:

우편복사 목록담기를 완료하였습니다.

*표시는 필수 입력사항입니다.

저장 되었습니다.